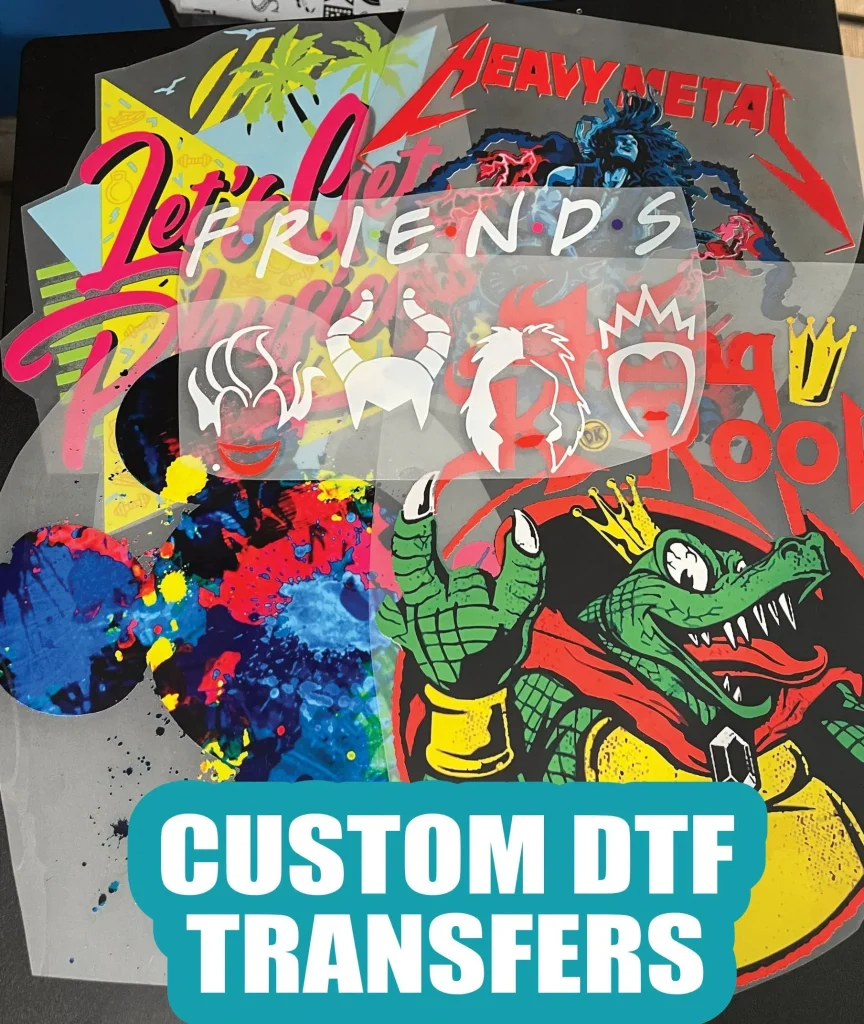

DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of custom apparel printing by combining quality and versatility in one seamless process. Unlike traditional methods such as screen printing and sublimation printing, DTF offers an innovative approach that allows users to apply vivid designs on a wide range of fabrics with ease. This groundbreaking technology applies specialized inks onto a film, which is then transferred to fabric using heat and pressure, making it accessible for both large-scale production and personalized pieces. With the ability to print on cotton, polyester, and blends, DTF simplifies the customization process, minimizing the restrictions often encountered with heat transfer vinyl. As the demand for unique apparel continues to rise, DTF transfers stand out as a compelling solution for both hobbyists and small businesses alike.

Direct-to-Film printing, also known as DTF printing, represents a dynamic shift in the landscape of textile design. This modern technique rivals other printing methods, including traditional screen printing, heat transfer vinyl, and even specialized sublimation printing, by offering compatibility with various fabric types without the stringent guidelines typically associated with these alternatives. DTF utilizes an effective method of transferring intricate designs by utilizing heat and pressure, ensuring high-quality prints that can withstand the test of time. As more creators and brands explore custom apparel options, the benefits of DTF become increasingly apparent, merging creativity with practicality for an exceptional printing experience.

What Is DTF Printing?

Direct-to-Film (DTF) transfer printing is revolutionizing the way custom apparel printing is conducted. This cutting-edge technique involves printing intricate designs onto a specialized film using high-quality inks that bond well with the film material. Once printed, a unique adhesive powder is applied, ensuring that the design can be permanently transferred onto various fabric types using heat and pressure. One of the most appealing aspects of DTF printing is its ability to produce vibrant colors and detailed graphics, making it ideal for personalized apparel.

Unlike traditional methods such as screen printing or sublimation printing, DTF offers a level of versatility and convenience that’s hard to match. DTF can be applied to a wide array of fabrics, including cotton, polyester, and blends, without the need for any special coatings. This flexibility allows artists and businesses to express their creativity without being confined to specific fabric types or designs.

Key Advantages of DTF Transfers

DTF transfers present several significant advantages over more established printing techniques. For instance, the application process is quicker and requires significantly less preparation. Where sublimation requires specific polyester fabrics, DTF transfers can adhere effectively to many different types of material. This versatility enhances the appeal for businesses looking to diversify their product offerings while still delivering high-quality prints to customers.

Additionally, the advancements in DTF technology have made it possible to produce durable prints capable of withstanding repeated washes without fading. As brands compete in a crowded market, having a printing method that ensures both quality and longevity is invaluable. This durability positions DTF as a practical choice for businesses focused on producing custom apparel that has lasting appeal.

DTF vs. Sublimation Printing

When comparing DTF with sublimation printing, it’s essential to recognize the inherent differences in process and application. Sublimation printing is renowned for yielding high-quality results, particularly on polyester fabrics. However, its limitations arise when it comes to application on other materials, restricting the designs significantly. On the other hand, DTF’s range allows it to cater to a broader spectrum of fabric types without requiring any specialized coatings, making it a more versatile option.

Moreover, diminutive production runs are often a challenge in sublimation as it typically demands larger batch sizes to justify the time and resources involved. In contrast, DTF printing’s straightforward application process facilitates rapid production, accommodating everything from one-off designs to larger orders. Consequently, for businesses seeking both efficiency and quality, DTF emerges as a competitive alternative.

Comparing DTF Transfers and Screen Printing

Screen printing remains one of the most popular methods for custom apparel production, especially when printing on a large scale. However, it’s often priced based on the number of colors in a design, requiring separate screens for each color, which can elevate setup costs significantly. DTF transfers offer a significant advantage here by allowing full-color designs to be printed onto a single film, eliminating high overhead costs associated with screen printing.

Furthermore, the vibrancy of colors achievable through DTF is steadily attracting interest as improvements have been made in DTF technology. The result is a quality that rivals traditional screen printing, combined with the added benefit of quick turnarounds and less labor-intensive processes. This combination makes DTF a strong contender against screen printing, especially for businesses focusing on high-quality, colorful designs.

Heat Transfer Vinyl vs. DTF Transfers

Heat Transfer Vinyl (HTV) has long been a go-to choice for those working on smaller quantities or personalized projects due to its affordability and ease of use. However, as printing technologies evolve, DTF transfers have emerged with a superior advantage, especially regarding design complication. While HTV requires cutting and weeding out the unwanted vinyl, which can be laborious, DTF allows for detailed designs to be printed directly onto the film, simplifying the entire process.

Additionally, while HTV may be durable, it often doesn’t offer the same longevity or versatility across different materials found in DTF printing. DTF can print a wider range of colors without needing varied vinyl sheets, which is especially beneficial for businesses that handle multiple projects with diverse design requirements. As a result, DTF transfers are becoming the preferred choice for those looking to embrace efficiency without compromising on quality.

Choosing the Right Printing Method for Your Needs

Selecting the best printing method for custom apparel largely depends on specific business requirements, including design complexity, fabric type, and production volume. For those who need to print across various fabric types without limitation, DTF transfers are a promising option that combines technological advancement with practical application. This adaptability enables creative freedom while still ensuring high-quality output.

For small business owners or hobbyists, the decision might also factor in turnaround times and costs. DTF printing is equipped to handle quick jobs and intricate designs with relative ease, which may be vital in meeting client demands or personal projects. Therefore, weighing the strengths and limitations of each method, especially how DTF compares with established techniques like screen printing and sublimation, is critical in making an informed decision.

Frequently Asked Questions

What is DTF printing and how does it differ from sublimation printing?

DTF printing, or Direct-to-Film printing, involves transferring designs printed on special film to fabric using heat. Unlike sublimation printing, which requires specific polyester fabrics for high-quality prints, DTF works on a wider range of materials such as cotton and blends. This versatility makes DTF a popular choice for custom apparel printing.

How do DTF transfers compare to screen printing for custom apparel?

DTF transfers provide several advantages over traditional screen printing, including lower setup costs for multicolor designs, vibrant prints without worrying about separate screens, and the ability to print on diverse fabric types. While screen printing is ideal for bulk orders, DTF’s efficiency and flexibility cater to smaller runs and intricate designs.

Can DTF transfers be used on any type of fabric?

Yes, DTF transfers are highly versatile and can be applied to a variety of fabrics, including cotton, polyester, and blends. Unlike heat transfer vinyl (HTV) or sublimation, DTF requires no special fabric coatings, broadening your options for custom apparel printing.

What are the benefits of using DTF transfers over heat transfer vinyl (HTV)?

DTF transfers simplify the printing process compared to HTV, which requires precise cutting of designs before application. DTF allows for complex designs without additional preparation steps and provides better durability and color vibrancy across multiple fabric types, making it an effective choice for businesses and personal projects.

Are DTF transfers durable and long-lasting?

Yes, DTF transfers are known for their durability. Advances in DTF technology ensure vibrant prints that can withstand multiple washes without fading or cracking, often outperforming traditional methods like screen printing and HTV in longevity.

Is DTF printing cost-effective for small businesses?

DTF printing is cost-effective for small businesses, as it minimizes setup costs associated with screen printing and allows for quick production of custom designs. The efficiency and versatility of DTF transfers make them an attractive option for businesses offering a diverse range of apparel printing services.

| Feature | DTF Transfers | Sublimation Printing | Screen Printing | Heat Transfer Vinyl (HTV) |

|---|---|---|---|---|

| Material Compatibility | Various fabrics including cotton and polyester | Primarily polyester or polymer-coated items | Good for bulk orders but may require specific fabrics | Mostly on cotton or blends, less versatility |

| Setup Costs | Lower, single film for full-color designs | Higher due to multiple screens for different colors | Moderate costs, scalable for larger orders | Affordable for small runs |

| Print Quality | High quality across various fabrics | Stunning on polyester but limited to that material | Good, but intricate designs may be compromised | Good but can be less durable |

| Process Complexity | Straightforward application | Requires specific fabric preparation | Complex for intricate designs | Labor-intensive due to design cutting |

| Durability | Highly durable, withstands multiple washes | Durable but limited to fabric types | Durability varies, can crack or fade | Durable but less versatile in fabric types |

Summary

DTF transfers present a powerful option in the realm of custom apparel printing for anyone seeking quality, versatility, and ease of use. This printing method not only adapts to various fabric types efficiently but also maintains vibrant, high-quality prints that stand the test of time, making it superior to more traditional methods like sublimation, screen printing, and HTV. As the demand for quick turnaround and creative flexibility rises among hobbyists and small business owners alike, DTF transfers emerge as the optimal choice for your custom printing needs. Embrace the future of printing by choosing DTF transfers, and let your creative ideas shine!