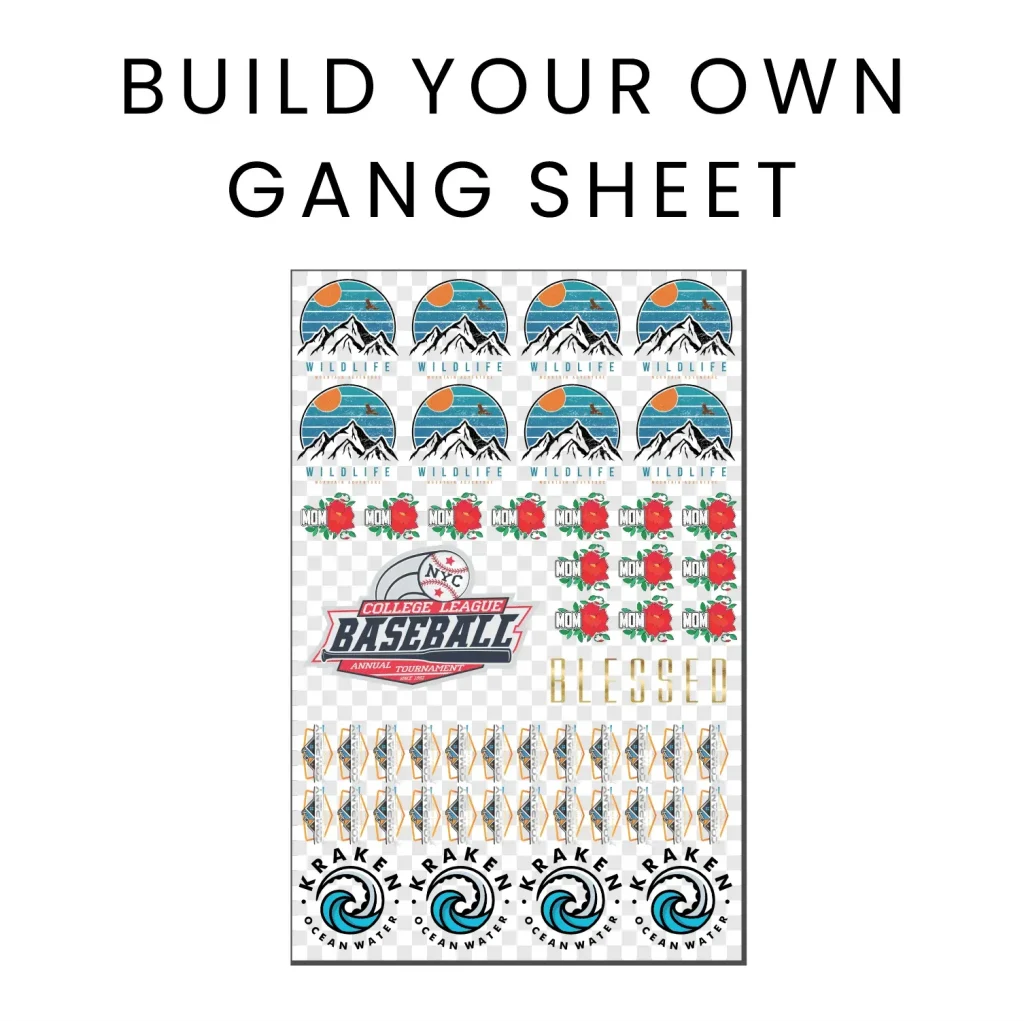

In the rapidly changing landscape of garment printing, the DTF Gangsheet Builder has emerged as a game-changer for businesses seeking to enhance production quality and efficiency. This innovative method offers a cost-effective alternative to traditional printing techniques such as screen printing and DTG printing, saving time and resources. The DTF Gangsheet Builder allows for multiple designs to be printed simultaneously, maximizing material usage while minimizing waste. As the demand for sustainable and high-quality garment printing grows, many companies are turning away from conventional methods in favor of this advanced technology. In this guide, we will delve into the advantages of the DTF Gangsheet Builder and how it revolutionizes the garment printing industry.

When it comes to innovative printing solutions, terms like DTF printing and gang sheet technology are becoming increasingly popular among garment makers. These methods stand in stark contrast to older techniques, such as traditional screen printing and digital printing, which often present limitations in efficiency and production costs. DTF, or Direct to Film, employs a unique technique that allows for vibrant and durable designs to be transferred onto various fabrics with remarkable ease. Moreover, the gangsheet approach enables printers to optimize their operations by consolidating multiple prints onto a single sheet, thereby reducing waste. As businesses explore these modern alternatives, understanding the benefits of DTF can be key to thriving in the competitive garment printing market.

Exploring the Benefits of DTF Gangsheet Builder for Garment Printing

The DTF Gangsheet Builder is revolutionizing the garment printing industry by offering a unique approach that maximizes both efficiency and versatility. Unlike traditional methods such as screen printing, which typically requires complex setups for each design, DTF allows multiple graphics to be printed on a single sheet. This not only saves on material costs but also reduces time significantly, making it ideal for orders of varying sizes and complexities. As consumer demand grows for personalized and trend-driven apparel, the DTF method emerges as a frontrunner for print shops striving to stay competitive.

Furthermore, the DTF Gangsheet Builder enhances the quality of prints through its innovative use of film technology. This means that the final output retains vibrant colors and sharp detail even on a variety of fabrics. Whether dealing with cotton, polyester, or mixed blends, DTF adapts seamlessly to different materials, offering garment printers a level of flexibility that traditional screen printing simply cannot match. The ability to produce high-quality prints on diverse surfaces positions DTF as a game-changing technique in the ever-competitive landscape of garment printing.

Cost-Effectiveness: The Economic Advantage of DTF Printing

One of the most significant advantages offered by DTF printing, particularly when utilizing the Gangsheet Builder, is its cost-effectiveness. In contrast to traditional screen printing, which can demand extensive upfront investment in equipment and materials, DTF simplifies the setup process by requiring fewer resources. This makes it particularly appealing for new businesses and small printing shops that seek to minimize initial costs while maximizing output.

Additionally, DTF printing leads to long-term savings through reduced ink consumption and material waste. The ability to efficiently print multiple designs on a single sheet translates to lower operational costs over time. As businesses strive for sustainable growth, optimizing production processes with techniques like DTF can enhance their profitability and market competitiveness, allowing print shops to meet client demands without compromising on quality or efficiency.

Environmental Impact: DTF Printing as a Sustainable Option

As the garment printing industry seeks to mitigate its environmental footprint, DTF printing stands out as a more eco-friendly alternative compared to traditional methods. Traditional screen printing methods often involve substantial waste due to the need for distinct screens for different colors, resulting in excess materials and increased pollution from chemical inks and solvents. In contrast, DTF printing employs a streamlined process that minimizes waste while promoting the use of less harmful materials, making it a sustainable choice for modern print shops.

In addition, DTF’s reliance on heat transfer and efficient ink usage contributes to a lower carbon footprint than traditional printing techniques. As the call for sustainable practices strengthens across industries, adopting DTF printing can enhance a company’s reputation as an environmentally conscious entity, attracting consumers who value ethical production methods in their purchasing decisions.

Comparing DTF and DTG Printing: Speed and Flexibility

When evaluating DTF printing against Direct to Garment (DTG) printing, speed and flexibility emerge as key differentiators. DTF can maintain rapid production times while allowing print providers to create multiple designs simultaneously, a game-changer for businesses that thrive on low-volume or custom orders. Conversely, DTG printing, while impressive in its detail and color reproduction, often falls short in terms of efficiency for larger tasks, which can frustrate businesses with tight deadlines.

This comparison emphasizes the adaptability of DTF printing, particularly for companies focused on quick turnaround times, whether fulfilling bulk orders or satisfying individual client requests. Manufacturers who rely on a diverse product portfolio benefit greatly from DTF’s capacity to accommodate various fabric types and print designs, allowing them to meet customer needs without extensive production delays or limitations.

Community Acceptance: The Growing Popularity of DTF Printing

The rapid rise in popularity of DTF printing in recent years speaks volumes about its effectiveness and ease of use. Many print shops and businesses have adopted DTF methods, leading to a wealth of shared experiences and resources within community forums and social media platforms. This sharing of knowledge not only boosts confidence among potential adopters but also fosters a collaborative environment where best practices can be widely discussed and implemented.

As more users report positive experiences with the DTF Gangsheet Builder, the method garners increased acceptance, proving it to be a valuable modern solution for garment printing. The enthusiasm surrounding DTF continues to grow, driven by user-generated content showcasing successful projects and tips for maximizing efficiency. The buzz surrounding this printing method illustrates a shift within the garment printing community towards innovation and adaptability in response to market needs.

The Future of Garment Printing: Trends and Innovations

Looking ahead, the garment printing industry is poised for significant transformations, with DTF printing leading the charge in innovation. The ongoing development of DTF technology is expected to usher in new trends that further streamline production processes while enhancing print quality. As manufacturers focus on the demand for customization and rapid fulfillment, advancements in DTF will likely reinforce its status as a preferred method among printers.

Additionally, as sustainability becomes a key concern for consumers and businesses alike, the DTF method’s ability to reduce waste and minimize environmental impact makes it an attractive option for environmentally conscious print shops. The convergence of trends towards customization, speed, and sustainability signifies that DTF printing will continue to play a pivotal role in shaping the future of garment printing, challenging traditional methodologies that may not keep pace with evolving consumer needs.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it compare to traditional printing methods?

The DTF Gangsheet Builder is an innovative printing technique that utilizes Direct to Film (DTF) technology to print multiple designs on a single sheet. This method streamlines garment printing processes, making it more efficient than traditional methods like screen printing and DTG printing, which often require longer setup times. DTF allows for quicker production rates with high-quality results, positioning itself as a favorable option for small to medium print runs.

How does DTF Gangsheet Building contribute to cost-effective printing?

DTF Gangsheet Building is known for its cost-effectiveness as it requires lower initial investments compared to traditional screen printing, which entails costly equipment like screens and squeegees. The ability to print multiple designs simultaneously reduces setup costs and minimizes waste, allowing businesses to meet market demands efficiently while maximizing profit margins.

Can DTF printing produce high-quality results compared to screen printing?

Yes, DTF printing can produce high-quality results that rival screen printing. The advancements in DTF technology allow for vibrant, high-resolution designs that are softer and more flexible on fabrics. Unlike screen printing, which can require separate screens for each color, DTF provides versatility with its application on various materials, yielding designs that are not only vivid but also durable.

Is DTF Gangsheet Builder an environmentally friendly printing method?

DTF Gangsheet Building is often regarded as more eco-friendly than traditional printing methods, such as screen printing. It generates less waste and utilizes fewer harmful chemicals in the production process. This focus on sustainability is increasingly important, particularly in an era where businesses are seeking greener solutions in garment printing.

What are the advantages of DTF printing for small businesses?

DTF printing presents several advantages for small businesses, including reduced setup costs, a shorter production time, and the ability to quickly fulfill smaller orders. Unlike traditional screen and DTG printing, DTF allows for efficient multi-design printing, enabling small print shops to respond rapidly to customer demands while maintaining high-quality output.

How does DTF printing fit into the current trends in garment printing?

DTF printing is gaining traction in the garment printing industry due to its user-friendly nature and efficiency. Many users and print shops report improved workflows and faster turnaround times, making it an attractive option for custom orders and small runs. As businesses strive to adapt to changing consumer preferences for unique and quick printing solutions, DTF technology aligns well with these current market trends.

| Key Feature | DTF Gangsheet Builder | Traditional Methods (Screen Printing & DTG) |

|---|---|---|

| Production Efficiency | High; prints multiple designs at once | Lower; requires lengthy setup for each design |

| Quality | High-resolution, soft, and flexible prints | Rich color vibrancy but less adaptable |

| Cost-Effectiveness | Lower upfront and long-term costs | Higher setup costs due to screens and squeegees |

| Environmental Impact | Lower waste and chemical use | Higher waste and chemical requirements |

| Trend Acceptance | Gaining popularity with print shops and forums | Established but facing new competition |

Summary

The DTF Gangsheet Builder represents a revolutionary method in garment printing, offering an innovative solution that enhances efficiency and reduces costs while ensuring high-quality outcomes. As businesses adapt to the competitive landscape, the integration of DTF printing technology is pivotal. This modernization not only streamlines production but also embraces sustainability, positioning brands to meet customer demands effectively. In the shifting environment of textile production, choosing the DTF Gangsheet Builder could be the key to transforming not only operational workflows but also the approach to garment printing for countless enterprises.