In recent years, **DTF transfers** (Direct-to-Film) have revolutionized the printing landscape, blending innovation with practicality to deliver high-quality prints. This modern technique allows artists and businesses alike to achieve vibrant and detailed fabric printing with ease, catering to an ever-growing demand for custom transfers. By utilizing advanced printing technology, DTF transfers not only ensure stunning visuals but also boast durability, making them ideal for various applications. As we delve into the world of DTF printing, you will discover how this method stands out among traditional printing techniques, and what exceptional advantages it offers for fabric enthusiasts. Join us on this exploration of DTF transfers and unlock the potential of your creative projects.

The emergence of **Direct-to-Film** transfers marks a significant transformation in the realm of fabric decoration and graphic printing. This innovative approach utilizes film as a medium for producing striking custom designs, enabling users to apply high-quality prints onto a wide array of fabrics seamlessly. As a favored choice among designers, the versatility of DTF printing not only accommodates intricate artwork but also guarantees long-lasting results through its robust application process. In this discussion, we will further explore the various aspects of DTF transfers, from their operational simplicity to the vibrant colors they offer, ensuring that both newcomers and seasoned professionals grasp the full potential of this cutting-edge printing method.

Understanding DTF Printing Technology

DTF printing technology, which stands for Direct-to-Film printing, is revolutionizing the way fabrics are printed. This innovative method enables designs to be printed onto a special film, which is then transferred onto a variety of fabrics using heat and pressure. One of the most remarkable features of DTF printing is its ability to produce high-quality prints with vibrant colors that capture attention. By utilizing a single film for multiple colors, DTF avoids the cumbersome setup typically required in traditional screen printing, simplifying the printing process and making it accessible even for smaller businesses.

In addition to vibrant colors, DTF printing offers unparalleled detail in design transfer. The process allows for intricate patterns and fine details to be preserved, resulting in sharp, professional-looking prints that stand out. Unlike other methods, such as DTG (Direct-to-Garment), DTF excels in durability, ensuring that prints maintain their integrity after numerous washes. This durability, combined with the high-quality outputs of DTF technology, positions it as a preferred choice for designers and businesses focused on custom fabric printing.

The Benefits of DTF Transfers

DTF transfers are gaining popularity not just for their aesthetic appeal but also for their practical advantages. One of the key benefits of using DTF technology is its versatility. Printshops can apply DTF transfers to a wide array of fabrics—from cotton and polyester to blends—unlike traditional methods that may be limited to specific materials. This flexibility allows businesses to cater to diverse customer needs, providing options for everything from sports apparel to high-fashion garments.

In addition to versatility, DTF transfers provide a level of quality and durability that is hard to match. The prints produced are not only visually striking but are also designed to withstand the test of time. They resist fading and cracking, ensuring that the designs remain vibrant and intact after multiple washes. As a result, businesses can promise their customers long-lasting quality, making DTF printing an appealing investment for those looking to enhance their product offerings.

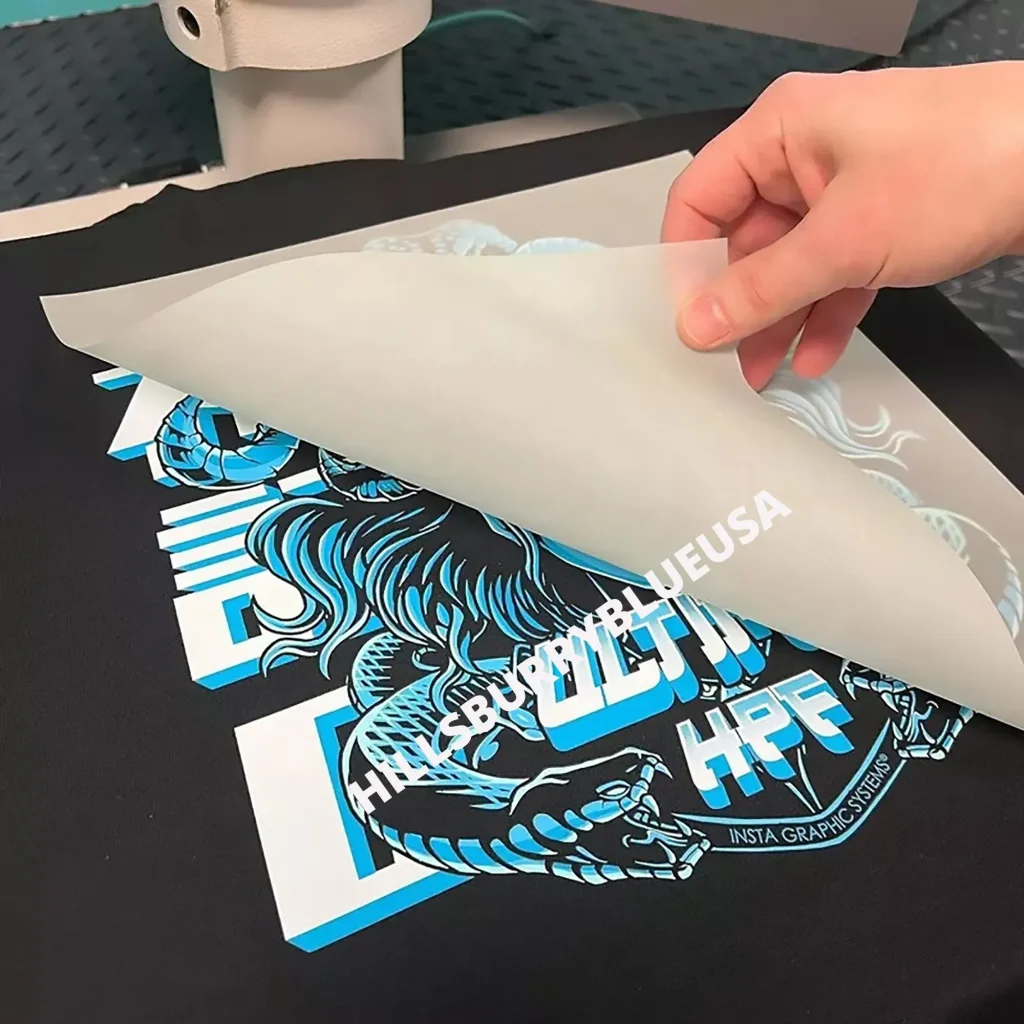

The Application Process of DTF Transfers

One of the key reasons for the rising popularity of DTF transfers is the straightforward application process. The method begins with printing the desired design onto a special film, which is then placed on the fabric. Using a heat press, the transfer process is completed by applying both heat and pressure. This simplicity makes DTF printing an attractive option for small businesses and DIY enthusiasts who wish to create custom designs quickly and efficiently.

Moreover, this ease of application eliminates the need for complex setups that other printing methods, such as screen printing, often require. This factor not only saves time but also reduces costs for businesses, allowing them to focus on creativity and customization without the constraints of traditional printing methods. As more people discover the accessibility of DTF transfers, the demand for this technique is expected to increase, further driving innovation in the fabric printing market.

Recent Technological Advancements in DTF Printing

The DTF printing industry has seen remarkable advancements that enhance both quality and usability for operators. Recent innovations have made DTF printers more affordable and accessible, breaking barriers for small and medium-sized enterprises. These upgrades involve user-friendly features such as auto-feeding mechanisms, enhanced speed settings, and superior ink formulations that improve adhesion and color vibrancy, leading to even more stunning and durable prints.

These technological strides ensure that DTF printers are not only cost-effective but also equipped to handle larger production runs with minimal labor input. Enhanced inks now provide better color retention and reduce the risk of fading, thus significantly boosting the overall quality of the final product. As these technologies continue to evolve, businesses are better positioned to meet consumer demand for high-quality, customized fabric prints, ensuring that they remain competitive in the ever-changing market.

Market Trends Impacting DTF Printing

The DTF printing market is experiencing robust growth driven by emerging trends in consumer preferences and technological innovations. The rise of e-commerce has accelerated the need for customized merchandise, and businesses are increasingly leveraging DTF transfers for cost-effective batch production. This trend allows brands to offer unique, personalized items that resonate with consumers, helping them stand out in a crowded marketplace. Additionally, the ability to produce high-quality prints on demand is appealing to businesses looking to minimize inventory costs while maximizing customer satisfaction.

Moreover, as the DTF printing community grows, a wealth of educational content is becoming available online. Tutorials, workshops, and comparative analyses are helping newcomers and veterans alike to navigate the advantages and methodologies behind DTF printing. With easy access to such resources, the barriers to adopting this technology are lowered, encouraging a broader audience to explore DTF as a viable printing solution for their creative projects or business needs.

Selecting the Ideal DTF Printer for Your Needs

Choosing the right DTF printer involves careful consideration of several crucial factors to ensure it aligns with your business objectives. Start with the initial cost: it’s vital to assess the budget and identify printers that offer the desired features within that range. Affordable, high-performance models are now available, making it easier for businesses to enter the DTF market and expand their printing capabilities.

Next, consider the ease of use of the chosen printer. User-friendly controls and a straightforward workflow can significantly enhance productivity and minimize learning curves for new operators. Lastly, the speed and output quality of the printer should not be overlooked. Investing in a DTF printer that delivers high-quality prints efficiently will not only satisfy customers but also enable companies to compete in a fast-paced market, solidifying their reputation for quality and reliability.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs on a specialized film that is then transferred to fabric using heat and pressure. This method allows for vibrant colors and sharp details, making it ideal for high-quality prints on various types of fabrics.

What are the benefits of using DTF printing for custom transfers?

Using DTF printing for custom transfers offers numerous benefits, including versatility across different materials, high-quality and durable prints that withstand washing, and a straightforward application process suitable for both businesses and DIY enthusiasts.

How does DTF printing compare to traditional screen printing?

DTF printing is generally more versatile than traditional screen printing, as it allows for complex designs with multiple colors to be printed on a single film. Additionally, DTF prints typically offer better detail retention and durability, making them a superior choice for many fabric printing applications.

What fabrics can be used with DTF transfers?

DTF transfers can be applied to a wide range of fabrics, including cotton, polyester, and blended materials. This versatility makes DTF printing suitable for various garment types and creative projects.

Are DTF transfers cost-effective for small businesses?

Yes, DTF transfers are highly cost-effective for small businesses due to the decreasing cost of DTF printers and the ability to produce high-quality custom prints without the need for large investments in complex printing setups.

What advancements are currently shaping the future of DTF printing?

Recent advancements in DTF technology include the release of more affordable printers, user-friendly features like auto-feeding, and enhanced ink formulations that improve color vibrancy and print durability, all contributing to the growth of DTF printing in the market.

| Key Features of DTF Transfers | Details | Benefits | |

|---|---|---|---|

| Versatility | Applicable to a wide range of fabrics, including cotton, polyester, and blends. | ||

| High Quality | Sharp details and durability against wear and washing. | ||

| Easy Application Process | Simple printing, placement, and heat application steps make it accessible for all users. | ||

| Recent Technological Developments | User-friendly features and enhanced inks improve print quality and accessibility. | ||

| Market Trends | Growing demand for customization in e-commerce and increased educational resources. | ||

Summary

DTF transfers represent a revolutionary advancement in the world of fabric printing, combining exceptional quality, versatility, and user-friendly processes. This innovative technology has made it easier for both businesses and individual creators to produce high-quality prints on various materials. With the rising trend of customization and the continuous improvement of DTF technology, businesses that embrace this method are well-positioned to meet the growing demands of the market. Understanding DTF transfers and their advantages will empower you to take advantage of the evolving landscape of printing solutions.