DTF printing, or Direct to Film printing, has rapidly emerged as a game-changer in the printing industry, revolutionizing how designs are transferred onto fabric. This cutting-edge technology facilitates the creation of striking visuals on various materials, making it a top choice for custom apparel printing and other creative projects. Its benefits are manifold, including high durability and the ability to print intricate designs with vivid colors. Whether for branding or personal use, the applications of DTF are boundless, encapsulating everything from fashion to promotional items. As DTF printing continues to gain momentum, it is redefining standards and expectations in the realm of modern printing.

Direct to Film (DTF) printing is reshaping the landscape of fabric printing, offering an innovative alternative to traditional techniques. This method utilizes specialized films to achieve exceptional image quality, making it ideal for those seeking custom solutions in apparel and merchandising. Not only does DTF technology yield high-resolution prints, but it also caters to a wide array of materials, enhancing its versatility in various applications. As the industry increasingly recognizes the advantages of this method, the growth of Direct to Film printing technology is becoming pivotal for businesses aiming to stay competitive in the custom printing market. The numerous benefits of DTF highlight its importance across different sectors, from fashion to promotional goods.

Understanding DTF Printing Technology

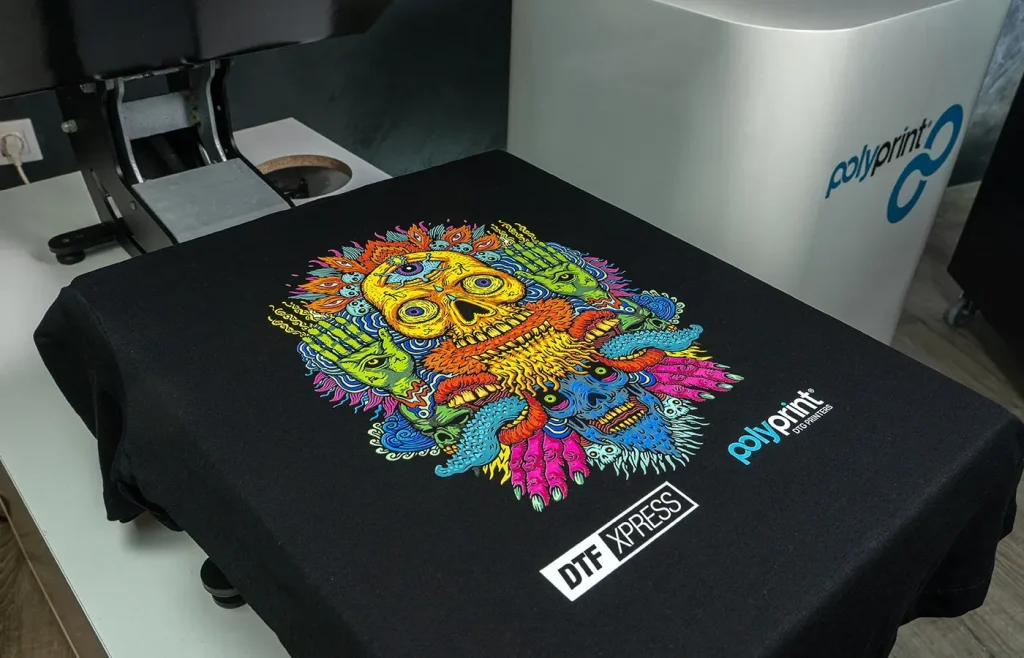

Direct to Film (DTF) printing technology has emerged as a game-changer in the custom printing landscape. Unlike traditional printing methods that require extensive setup time and specialized equipment, DTF printing simplifies the process by allowing artists and businesses to transfer high-quality images directly onto film. This film is then heat-pressed onto various substrates—whether it be fabrics, plastics, or leather—creating vibrant and durable designs instantly. The technology behind DTF uses advanced ink formulations that enhance color vibrancy and detail, making it a preferred choice for detailed graphics.

Moreover, the versatility of DTF printing technology plays a crucial role in its widespread adoption. Whether optimizing for small runs or large orders, DTF can cater to both needs seamlessly. As competition in the custom apparel printing industry grows, businesses leveraging DTF technology can provide a unique selling point to their customers, showcasing not just quality prints but also quick turnaround times. This adaptability to various textiles and the ability to produce intricate designs efficiently positions DTF printing as a frontrunner in the future of the printing industry.

Key Benefits of DTF Printing

The benefits of DTF printing extend far beyond vibrant color outputs. One of the primary advantages of this method is its cost-effectiveness, especially for businesses focused on custom apparel. Traditional printing techniques, such as screen printing, often demand higher setup costs and minimum order quantities, making DTF a financially viable option for small businesses or individuals looking to create personalized items. The ability to print on demand allows for flexibility—if a design doesn’t sell, there are minimal financial losses, unlike with bulk orders in traditional methods.

In addition, DTF technology contributes to environmentally friendly practices in the printing sector. With a focus on reducing waste, businesses can use DTF printing to create just-in-time production models. This not only minimizes inventory costs but also lowers the environmental footprint associated with mass production. Ultimately, the benefits of DTF printing are driving growth in this niche market, appealing to environmentally conscious consumers and businesses seeking sustainable practices.

Applications of DTF Printing Across Industries

The versatility of DTF printing opens a multitude of applications across various industries, most notably in custom apparel. DTF technology is perfect for creating personalized clothing items such as t-shirts, hoodies, and uniforms, allowing both businesses and individuals to express their unique style or brand identity. The ability to print on diverse fabrics, from cotton to polyester and even leather, broadens the horizon for designers and caters to a wide audience.

Furthermore, DTF printing is gaining traction in the promotional products sector. Businesses can easily produce custom merchandise for giveaways, events, or promotional campaigns, effectively enhancing their brand visibility. Not limited to apparel, DTF printing expands into home decor items, allowing for customization of cushions, bags, and various textiles, thereby capturing a broader market. This adaptability makes DTF not only a valuable tool for personal expression but also a solution for companies looking to increase their product lines.

The Future of DTF Printing in Custom Apparel

As the demand for personalized products continues to rise, the future of DTF printing in the custom apparel market looks incredibly promising. Recent innovations in DTF technology emphasize not just quality and efficiency but also the ability to quickly adapt to fashion trends. Businesses that adopt DTF printing can meet the ever-changing demands of consumers who seek unique, tailored products that stand out in a crowded marketplace.

Moreover, the continuous advancements in printing equipment and ink formulations are set to enhance the capabilities of DTF printing. It opens doors for more intricate designs, faster production times, and even reduced costs per print. As companies harness the power of DTF technology, they not only enhance their operational efficiencies but also foster a closer connection with their customers through bespoke offerings that resonate with modern consumer desires.

Challenges and Innovations in DTF Technology

While DTF printing presents numerous advantages, it also faces challenges that innovators in the field are working to address. One of the critical hurdles is ensuring the quality and longevity of prints, particularly when applied to various materials. While DTF films are designed to produce durable finishes, the technology must continually evolve to ensure that prints remain vibrant through multiple washes and wear. Developing advanced inks and coatings is essential to overcoming these challenges.

Additionally, as DTF technology gains popularity, competition will inevitably increase, prompting manufacturers to innovate further. Companies are investing in research to create more efficient transfer films and eco-friendly inks to align with sustainability goals. The future innovations in DTF technology will likely focus on improving print quality while streamlining production processes to make DTF a more accessible and appealing option for businesses of all sizes.

Embracing DTF Printing for Business Growth

For businesses looking to stay competitive in the custom printing industry, embracing DTF printing could be the key to unlocking new growth opportunities. The ability to provide high-quality, personalized products that meet customer demands quickly not only enhances customer satisfaction but also drives brand loyalty. Companies that invest in DTF technology are better positioned to capitalize on personalization trends, which are increasingly favored by consumers seeking individuality in their purchases.

Furthermore, as DTF printing continues to evolve, businesses can leverage emerging markets such as print-on-demand services, allowing them to minimize inventory costs while still catering to consumer needs. This approach opens up a world of possibilities for entrepreneurs and small businesses, enabling them to operate with greater agility and respond swiftly to market changes. By leveraging the advantages of DTF printing, companies can solidify their place in the evolving landscape of custom apparel and beyond.

Frequently Asked Questions

What is DTF printing and how does it work?

DTF printing, or Direct to Film printing, is a technique that involves transferring images onto a special film which is then applied to fabrics using heat and pressure. This process allows for vibrant colors and high-resolution graphics, perfect for custom apparel and various substrates.

What are the benefits of DTF printing compared to traditional printing methods?

The benefits of DTF printing include high-quality output with vibrant and detailed images, durability that withstands wear against time, and versatility to print on multiple materials like cotton and polyester. Additionally, it is cost-effective for short runs and custom designs, making it a favorite among small businesses.

What industries can benefit from the applications of DTF printing?

DTF printing has a broad range of applications across industries such as custom apparel (T-shirts and hoodies), promotional products for events, home decor items like pillowcases, and branded accessories including caps and tote bags. Its versatility allows it to cater to diverse market needs.

How does DTF printing technology improve the quality of prints?

DTF printing technology enhances print quality by using specialized inks and transfer films that create vibrant colors and intricate designs. The high-resolution capabilities of DTF ensure that visuals are clear and appealing, making it ideal for detailed custom apparel projects.

Is DTF printing suitable for small businesses looking to enter the custom printing market?

Yes, DTF printing is highly suitable for small businesses due to its cost-effectiveness and efficiency in handling short print runs. This technology is accessible and allows small enterprises to offer personalized products without expensive overheads.

What is the future of DTF printing in the printing industry?

The future of DTF printing looks promising as ongoing technological advancements improve printer, ink, and film quality. With increasing consumer demand for customization and sustainable practices, DTF printing is poised to become a key player in the print-on-demand landscape, benefiting both entrepreneurs and established businesses.

| Key Point | Details |

|---|---|

| What is DTF Printing? | A process that transfers images onto a special film, which is then applied to fabric, allowing for vibrant, high-resolution prints on various substrates. |

| Recent Developments | Major companies like Insta Graphic Systems, Epson, Sam’s DTF Transfers, and AM.CO.ZA have introduced innovative solutions, enhancing DTF technology accessibility and efficiency. |

| Advantages of DTF Printing | High-quality output, durability, versatility across materials, and cost-effectiveness for short runs make it a preferred choice. |

| Applications of DTF Printing | Used in custom apparel, promotional products, home decor, and accessories, DTF caters to a wide array of markets. |

| Future of DTF Printing | With ongoing advancements and the rising demand for personalization, DTF is positioned to grow significantly in the print-on-demand market. |

Summary

DTF printing is redefining the landscape of the printing industry with its innovative approach to producing vibrant and high-quality prints. As it gains traction among businesses and consumers, understanding the implications of DTF printing becomes essential. Its versatility and capacity to adapt to various materials make it an attractive option for custom coloring, from apparel to promotional merchandise. As more advancements are made and the market demands shift towards personalized solutions, DTF printing is poised to become an indispensable tool in modern printing ventures.