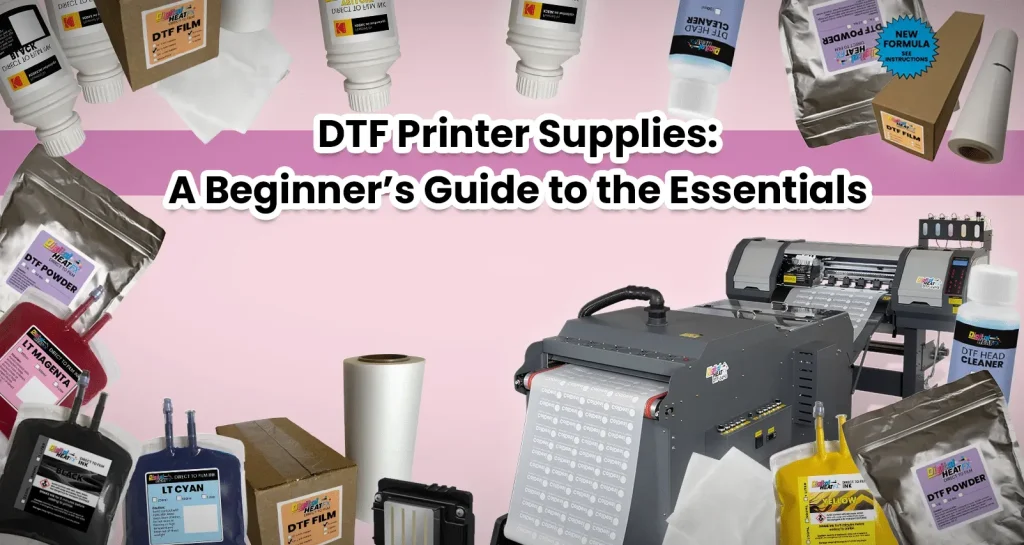

DTF supplies are essential for anyone looking to master the art of Direct-to-Film (DTF) printing, a method that has revolutionized the custom apparel industry. This innovative process involves high-quality printing onto transfer films, enabling vibrant designs to be effortlessly applied to various fabrics. With the right DTF supplies—including specialized transfer films, eco-friendly DTF inks, and precision heat press tools—you can elevate your printing game and produce eye-catching garments. The combination of these printing materials not only ensures durability and flexibility but also enhances your creative capabilities. As the demand for personalized apparel grows, understanding and utilizing DTF supplies effectively can set you apart in this competitive market.

When discussing DTF supplies, one can also refer to these components as essential resources for Direct-to-Film printing, a rapidly emerging technology in garment decoration. These resources encompass everything from specialized transfer films and innovative inks to necessary heat pressing equipment that facilitates the transfer process. Each item plays a critical role in ensuring high-quality outputs and enhances the overall printing experience for creators and businesses alike. In addition to traditional materials, alternative options like powder adhesives have surfaced, contributing to the versatility in DTF applications. As the industry evolves, staying updated with these valuable printing resources is key to achieving remarkable results in customized textiles.

Understanding the Basics of DTF Printing

Direct-to-Film (DTF) printing is a transformative process that allows for the direct application of designs to various fabrics using a unique printing technique. This method bridges the gap between conventional screen printing and direct-to-garment (DTG) printing, merging benefits from both to achieve stunning results. DTF prints are created using specialized transfer films that are coated to hold the ink crisp and firm, ensuring the designs maintain their vibrancy even after repeated washes. It’s this versatility and detail that makes DTF printing a preferred choice among designers.

In addition to the aesthetic benefits, DTF printing is lauded for its efficiency. The entire process, from printing to application, can be streamlined, saving both time and resources for businesses looking to fulfill custom orders quickly. This speed is crucial in the fast-paced world of fashion and merchandise, where turnaround time can make or break a deal. Furthermore, the ability to print on-demand not only reduces waste but also allows for personalized garment creations, aligning with current consumer trends toward individualization.

Essential DTF Supplies You Need

The success of DTF printing heavily relies on the right supplies. Among the key components are the transfer films, inks, and powder adhesives that play vital roles during the printing process. Transfer films, typically composed of PET, come in various types, each optimized for specific fabrics and inks. Choosing the right film is crucial; the thickness and quality can greatly influence the final print’s durability and clarity. It’s essential for printers to have a solid understanding of which supplies work best with their specific printing machine.

Moreover, the quality of DTF inks cannot be overlooked. Water-based inks are the most common choice, praised for their environmentally friendly properties and excellent adhesion to both films and fabrics when heat is applied. Providers like Kornit and Epson offer high-quality inks that withstand fading, ensuring that once applied, the designs retain their original vibrancy despite washing and wear. This combination of the right films and inks, along with effective powder adhesives, culminates in a high-quality print that stands the test of time.

The Role of Heat Press Tools in DTF Printing

Heat press tools are arguably one of the most critical aspects of the DTF printing process. These machines provide the necessary heat and pressure required to transfer designs from the film onto the fabric. Different models are available, ranging from manual presses to advanced automatic options that feature precise digital controls for temperature and pressure. This technology helps in achieving consistent results, reducing the margin for error that could jeopardize a print job.

In the ever-evolving DTF printing landscape, staying equipped with the latest heat press technology is essential for businesses that wish to ensure efficiency and quality in their production lines. The right heat press not only enhances productivity but also maximizes the accuracy of transferring designs, thereby boosting customer satisfaction. As the demand for personalized apparel grows, understanding and investing in quality heat press tools becomes indispensable for achieving professional-grade outcomes.

Exploring Different Types of DTF Transfer Films

When it comes to DTF printing, the type of transfer film used can significantly impact the overall result. There are various kinds of transfer films available, such as clear films and colored films, which cater to different printing needs. Clear films are generally used for designs requiring transparency to avoid color distortion, while colored films are perfect for vibrant, opaque designs. It’s crucial for printers to evaluate which type fits their creative vision and the fabrics they’re working with.

Additionally, some films have advanced features like stretchability, making them suitable for elastic materials, which is an added advantage in clothing manufacturing. The advancements in film technology not only mitigate issues like cracking or peeling post-application but also improve the overall feel of the printed garment. Making informed choices about transfer films enables businesses to consistently produce high-quality prints that meet customer expectations.

Latest Innovations in DTF Inks

The evolution of DTF inks has been astounding, with significant advancements made to improve print quality while considering environmental impact. Modern DTF inks are water-based and formulated for superior adhesion and flexibility, allowing for high-quality prints that can withstand washing and wear. Many brands are now offering eco-friendly ink options that do not compromise on vibrancy or performance, aligning with the growing demand for sustainable practices in the textile industry.

Moreover, these innovations in DTF inks have opened new avenues for creativity. With improved formulations, printers can explore more intricate designs that require a broader color spectrum, ensuring that even the most complex graphics can be rendered beautifully. As competition increases in the custom apparel market, those who stay ahead with the latest ink technologies will likely see a distinct advantage in terms of customer satisfaction.

The Growing Community and Resources for DTF Printing Professionals

As DTF printing continues to gain popularity, so does the community surrounding it. Countless online forums, groups, and educational workshops have emerged, catering to both novices and seasoned professionals. These platforms serve as invaluable resources, allowing users to exchange tips, troubleshoot issues, and share best practices. Engaging with a DTF community can greatly enhance one’s knowledge and skills, making the learning curve less daunting for newcomers.

Additionally, many educational resources delve into the practicalities of using DTF supplies effectively, maximizing print quality, and maintaining equipment. These communities often organize events and webinars that keep members updated on the latest trends and advancements in DTF technology, ensuring that everyone has access to current knowledge and techniques. As the industry grows, participating in these communities will be essential for anyone looking to thrive in the DTF printing landscape.

Frequently Asked Questions

What are DTF supplies and their importance in printing?

DTF supplies encompass all the essential materials needed for Direct-to-Film (DTF) printing, including transfer films, DTF inks, and heat press tools. They are crucial for creating high-quality, vibrant prints that adhere well to various fabrics, making them integral to custom apparel production.

What types of transfer films are used in DTF printing?

In DTF printing, specialized PET (Polyethylene Terephthalate) transfer films are used. These films are designed for ink adhesion and come in various sizes and thicknesses, directly affecting print quality. Brands like StarPrint and Cenovus are popular choices, optimized for use with diverse inks and fabrics.

What kind of inks are suitable for DTF supplies?

DTF inks are typically water-based and formulated for strong adhesion and flexibility. They effectively bond to transfer films and fabrics when heat is applied. Eco-friendly pigment inks from brands like Kornit and Epson are becoming increasingly popular due to their vibrant color retention and environmental benefits.

Do I need any specific heat press tools for DTF printing?

Yes, a quality heat press is essential for DTF printing. It must provide the appropriate heat and pressure to transfer the design from the transfer film onto the fabric successfully. Advanced models with features like digital temperature controls significantly enhance the accuracy and efficiency of the printing process.

What role do powder adhesives play in DTF supplies?

Powder adhesives are vital in DTF printing as they ensure the ink on the transfer film adheres correctly to the garment during the heat transfer. The consistency and quality of the powder adhesive, applied using tools like the DTF Powder Shaker, influence the final product’s feel and durability.

How can I learn more about DTF printing and its supplies?

To learn more about DTF printing and its supplies, consider joining online communities or attending educational workshops that focus on DTF techniques. These platforms provide valuable insights, troubleshooting tips, and best practices to enhance your DTF printing projects and stay updated with the latest advancements.

| Key Point | Description |

|---|---|

| Overview of DTF Printing | DTF printing allows for high-quality prints on transfer films, suitable for various fabrics, which has made it popular in the custom apparel industry. |

| Transfer Films | Specialized PET films that accept ink, available in various sizes and thicknesses, affecting print quality and durability. Notable brands include StarPrint and Cenovus. |

| Inks | Water-based inks designed for flexibility and strong adhesion, with advancements focusing on environmentally friendly options from manufacturers like Kornit and Epson. |

| Printers | Modified inkjet printers, like the Epson SureColor and Roland VersaUV, are used for DTF applications, enhancing accessibility for small enterprises. |

| Powder Adhesives | Powder adhesives play a crucial role in securing the ink to the garment during heat transfer; the application quality is vital for print consistency. |

| Heat Presses | High-quality heat presses apply the necessary heat and pressure for successful transfers, with various models available to enhance usability and accuracy. |

| Recent Developments | The DTF market is expanding, focusing on sustainability with eco-friendly products and nurturing community education about DTF techniques. |

Summary

DTF supplies are at the forefront of innovation in custom apparel printing, providing essential materials and tools for high-quality garment decoration. The versatility and vibrancy of DTF printing, supported by specialized transfer films, eco-friendly inks, and efficient printing equipment, make it a valuable technique for artists and businesses alike. As sustainability becomes more integral to manufacturing, the DTF industry is evolving with a focus on environmentally conscious practices. With a growing community of educators and resources, those entering this field can enhance their skills and outputs, positioning themselves for success in the booming market of DTF printing.