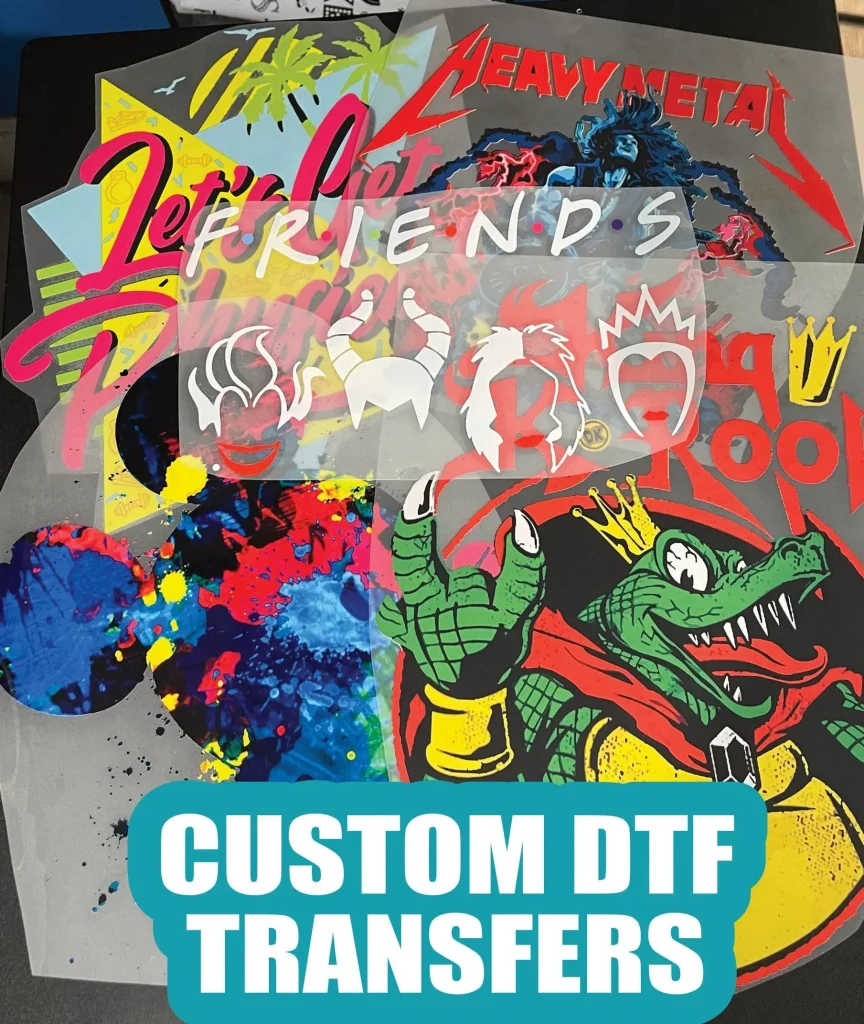

DTF transfers, or Direct-to-Film transfers, are revolutionizing the world of textile printing with their unmatched quality and versatility. This innovative printing technique allows users to create vibrant, intricate designs on fabric, making it a favorite among custom apparel creators. The DTF transfer process combines high-quality films and specialized inks to ensure exceptional adherence and durability. Whether you’re a beginner or a seasoned professional, understanding the best practices for DTF is essential for achieving stunning results. In this guide, we’ll walk you through essential DTF printing techniques and provide you with invaluable DTF transfer tips to perfect your creations.

In the realm of fabric printing, direct-to-film applications are rapidly gaining popularity for their remarkable ability to produce high-definition images. This method, often referred to as DTF printing, involves a meticulous approach of transferring designs from film straight onto textiles. By utilizing advanced film technology and specific inks, printers can achieve an impressive vibrancy and detail that other methods often struggle to replicate. With the right knowledge of the DTF transfer process, including effective techniques and essential preparation tips, practitioners can optimize their output and ensure long-lasting results.

The Benefits of Direct-to-Film Printing

Direct-to-Film (DTF) printing is revolutionizing the textile industry with its ability to produce stunning and detailed designs. One of the primary benefits of DTF transfers is their vibrant color reproduction, which brings artwork to life, making it ideal for custom apparel. Unlike traditional methods, DTF printing allows for printing on a wider variety of fabrics, including cotton, polyester, and blends. This versatility opens up new possibilities for designers and businesses looking to create unique garments.

Moreover, DTF transfers are known for their durability. They withstand multiple washes while retaining their colors and details, providing an excellent return on investment for businesses. The ease of application, coupled with the ability to print both small and large batches efficiently, makes DTF an attractive option for personalized items, ensuring that customers receive high-quality products every time.

Essential Materials for Perfect DTF Transfers

To achieve flawless DTF transfers, selecting the right materials is critical. First, invest in high-quality DTF film, as it is the backbone of the printing process. The film should be compatible with your DTF printer and ink, which enhances the overall print quality. Pairing this film with specialized DTF inks ensures vibrant colors and strong adhesion to the fabric, helping to prevent any issues during the transfer process.

Another key material is the powder adhesive, which is necessary for fixing the design onto the fabric. It plays a crucial role in the curing phase, ensuring that the print adheres properly. Additionally, having a reliable heat press is essential to apply the right amount of heat and pressure needed for a successful transfer. Investing in these materials will pay off by enhancing the quality and durability of your DTF prints.

Preparing Your Images for DTF Printing

Preparing your images properly is a vital step in the DTF transfer process. Begin by ensuring your artwork is in the correct format—PNG or BMP is typically best—and that it adheres to the CMYK color profile. This attention to formatting helps in achieving accurate color representations on the fabric. Incorrect details at this stage can lead to disappointments later in the printing process.

Creating mockups is also a recommended practice. At this stage, visualize how your design will appear on the fabric. Running test prints can be beneficial in identifying any adjustments that may be required for the final product. This preparatory stage lays the foundation for a smooth DTF transfer experience, minimizing errors and ensuring high-quality results.

Optimizing Printer Settings for DTF Transfers

Setting up your printer correctly is crucial to the success of your DTF transfers. First, ensure the printer is set to a minimum of 1440 DPI, which is essential for producing detailed and sharp prints. This setting directly affects the quality of the final design, and neglecting it can result in blurry or pixelated images on the fabric.

Additionally, adjust your printer’s media type settings to ‘Transfer’ or as recommended by the DTF film manufacturer. This adjustment optimizes ink usage and enhances the quality of the print output. Proper printer management ensures that every aspect of the printing process is geared towards achieving the highest quality results, which is vital in a competitive market.

Common Mistakes to Avoid in the DTF Transfer Process

When embarking on the DTF transfer process, being aware of common pitfalls can save a lot of frustration. One significant mistake is using low-quality materials, which can lead to unsatisfactory results and complaints from customers. Always opt for reputable brands for DTF films and adhesives to ensure a successful transfer.

Another common error is neglecting printer settings or failing to perform consistent quality checks between prints. Inaccurate settings often result in poor image quality or transitions. Furthermore, overlooking the importance of post-care for the finished garment can lead to premature wear and peeling. Following best practices diligently reduces these risks and enhances the overall quality of your DTF prints.

Post-Transfer Care for DTF Printed Garments

Proper post-transfer care is essential for maintaining the vibrancy and durability of DTF printed garments. After transferring your design, consider placing protective paper over the transfer and pressing it again briefly. This procedure helps bond the ink more solidly to the fabric, ensuring better longevity.

Additionally, washing garments inside out on a gentle cycle is recommended, as it protects the print during the washing process. Airdrying the items further preserves the integrity of the print. Ignoring these simple steps can lead to designs fading or peeling, which could detract from the quality of your work. By investing time in care, you help ensure that your DTF creations look great for years to come.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing a design onto a special film that is then heat-transferred onto fabric. This method allows for vibrant colors and intricate details, making it ideal for custom apparel. The DTF transfer process includes several steps: printing the design, applying powder adhesive, and using a heat press to transfer the design onto the garment.

What are the best practices for DTF printing?

To achieve the best results with DTF printing, follow these best practices: use high-quality DTF films and inks specifically designed for this process. Ensure optimal printer settings with at least 1440 DPI, choose the correct media type for transfers, and properly cure the design before transferring for durability. Always test your designs with mockups before proceeding with the final print.

Can I use any printer for DTF transfers?

Not all printers are suitable for DTF transfers. You need a DTF printer that is compatible with DTF films and inks. Look for printers specifically designed for textile printing and ensure it meets the required specifications for optimal quality in DTF printing techniques.

What adhesives are used in the DTF transfer process?

The DTF transfer process requires a powder adhesive that helps fix the ink to the fabric during the transfer. It’s crucial to apply the adhesive evenly over the printed area while the ink is still wet to ensure complete coverage. This adhesive is melted during curing to bond the ink and fabric effectively.

What common mistakes should I avoid when doing DTF transfers?

Common mistakes to avoid in the DTF transfer process include using low-quality materials, misconfiguring printer settings, and neglecting post-care instructions. Ensuring you use reliable DTF films and adhesives, adjusting printer settings accurately, and following recommended post-transfer care will enhance the quality of your prints.

How should I care for garments after a DTF transfer?

To care for garments with DTF transfers, wash them inside out on a gentle cycle and air dry to maintain the quality of the print. For added durability, consider placing protective paper over the transfer and pressing it again for about 10 seconds after the initial transfer to help the ink bond better.

| Step | Description |

|---|---|

| Understanding DTF Transfers | DTF transfers involve printing designs onto film for heat transfer to fabric, providing vibrant colors and details. |

| Step 1: Gather Your Materials | Collect DTF printer, film, powder adhesive, heat press, and protective paper. |

| Step 2: Preparing Your Images | Format images appropriately and create mockups before printing. |

| Step 3: Printer Settings | Set printer DPI to at least 1440 and adjust media type. |

| Step 4: Printing Your Designs | Load film and print your design following color management. |

| Step 5: Applying Powder Adhesive | Sprinkle adhesive on wet ink and shake off excess. |

| Step 6: Curing the Print | Cure adhesive in a heat source for 30 seconds at 160-180°C. |

| Step 7: The Transfer Process | Align cured film on garment and press with heat for 15-20 seconds. |

| Step 8: Peeling the Film | Carefully peel the film back after cooling to check the transfer. |

| Step 9: Post-Transfer Care | Press again, wash inside out, and air dry for durability. |

| Common Mistakes to Avoid | Use quality materials, accurate settings, and proper post-care. |

Summary

DTF transfers are revolutionizing the world of textile printing with their ability to achieve stunning and durable designs. To master the DTF transfer process, it is essential to follow a systematic approach from selecting high-quality materials to executing meticulous post-transfer care. Each phase in the process contributes significantly to the quality of the final product, making it vital for professionals in the industry to adhere to these steps. Emphasizing precision and using the right tools leads to beautiful prints that stand out in the fashion and customization markets. By applying these techniques, you can experience the remarkable results of your DTF transfers and elevate your printing projects to a new level.