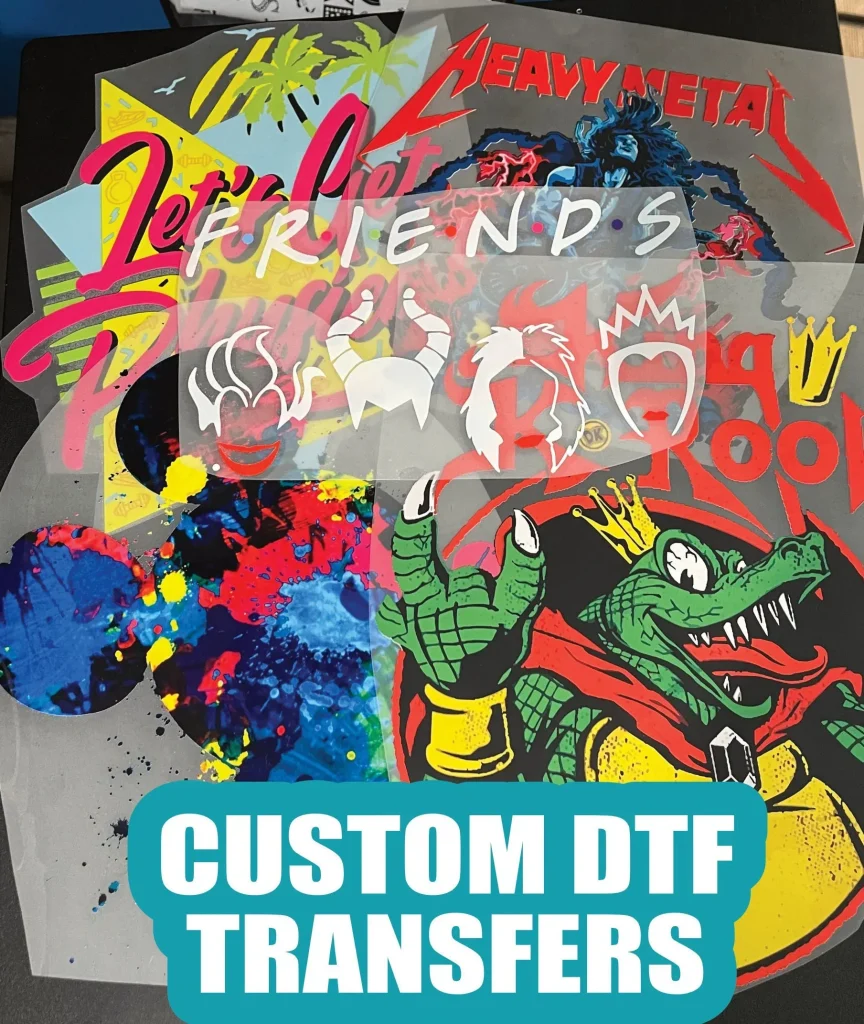

DTF transfers, short for Direct to Film transfers, represent a groundbreaking advancement in the realm of custom apparel. This exciting print technology allows for vibrant, full-color designs to be effortlessly transferred onto garments, particularly T-shirts, revolutionizing the standard practices of T-shirt printing. As more businesses and hobbyists alike embrace DTF printing, the demand for high-quality, durable, and unique designs grows exponentially. This post delves into the mechanics and advantages of DTF transfers, offering insights into how this innovative method meets the diverse needs of today’s consumers. Whether you’re looking to start a custom apparel line or enhance your existing offerings, understanding the potential of DTF can elevate your printing game significantly.

In the world of fabric decoration, the recently popularized Direct to Film (DTF) method has emerged as a fan favorite for many professionals in T-shirt production. This innovative approach to apparel customization not only simplifies the printing process but also enhances the quality of designs, allowing for multiple color applications with remarkable precision. Commonly referred to as film printing or transfer printing, this technology provides businesses with flexibility and efficiency that traditional methods often lack. By utilizing DTF techniques, creators can cater to a wider audience, producing both small and large batches of custom designs without the extensive setup associated with earlier printing technologies. This makes DTF an essential option for anyone looking to delve into the world of T-shirt printing, ultimately transforming how custom apparel is created and marketed.

Understanding the Fundamentals of DTF Printing

DTF printing, short for Direct to Film transfer printing, has revolutionized the custom apparel industry. This innovative technology involves printing graphics onto a special film, which is then heat pressed onto fabric. Unlike traditional methods such as screen printing, DTF gives designers greater flexibility with color gradients and intricate designs. It enables full-color prints that maintain their vibrancy and quality even after multiple washes, making it a standout choice for T-shirt printing.

The appeal of DTF transfers lies in their versatility. The process allows for printing on a range of fabrics, including cotton, polyester, and blends. This means businesses can cater to diverse customer needs without worrying about material constraints. The ability to achieve high-quality prints makes DTF an attractive option for small custom apparel companies and large-scale brands alike, bridging the gap between affordability and quality.

The Advantages of DTF Transfers Over Traditional Methods

One of the standout advantages of DTF transfers is the reduction in waste. Traditional printing methods often require multiple setups and screens for different colors, leading to higher material costs. In contrast, DTF printing utilizes a digital approach, which not only minimizes waste but also speeds up the production time. This efficiency is critical for small businesses or individual creators who want to efficiently fulfill custom orders without excessive expenditure.

Moreover, DTF printing comes without the constraints of minimum order quantities. Businesses such as Sam’s DTF Transfers offer the flexibility of no minimum orders, enabling small-scale operations or hobbyists to produce custom designs tailored to niche audiences. This opens up opportunities for creative individuals to explore their designs without committing to large quantities that may not sell, leading to a more sustainable and creative enterprise.

Recent Innovations in DTF Printing Technology

Recent developments in DTF technology are paving the way for more efficient and accessible printing solutions. Companies like Snuggle have introduced platforms that streamline the entire printing process, eliminating the need for extensive equipment and knowledge. This democratization of printing technology allows even small businesses to operate with a professional edge, enhancing their product offerings in the competitive apparel market.

In addition, software solutions by DTFPrinter now help crafters produce custom transfers more easily, addressing the common challenges faced by individual creators. By simplifying the production process, these innovations not only cater to the home crafting community but also ensure high-quality results, positioning DTF as a game-changer in the realm of custom T-shirt printing.

Why Businesses are Turning to DTF Transfers

As the demand for personalized products continues to rise, businesses are increasingly leaning towards DTF transfers for their custom apparel needs. The ability to create unique designs quickly and cost-effectively makes DTF printing a favorite among startups and established brands alike. In an environment where consumers seek one-of-a-kind items, DTF provides the perfect balance of creativity and practicality, ensuring that businesses can keep up with evolving trends.

Additionally, DTF transfers offer significant cost savings as compared to traditional printing methods. This cost-effectiveness is particularly beneficial for small businesses that may not have extensive budgets for equipment and materials. By adopting DTF technology, these businesses can invest more in marketing and design rather than on the operational logistics of printing, leading to better growth opportunities.

Durability and Quality: Key Benefits of DTF Transfers

Durability is a crucial factor when it comes to custom apparel, and DTF transfers excel in this area. Prints made with DTF technology are designed to withstand repeated washing and wearing, ensuring that vibrant colors and fine details remain intact over time. This quality not only enhances customer satisfaction but also strengthens brand reputation as users are more likely to recommend products that last.

Moreover, the ease of application associated with DTF transfers adds to their appeal. The straightforward process of printing, cutting, and heat pressing means that even businesses with limited experience in T-shirt printing can achieve professional results. This user-friendly approach allows for quick turnaround times, enabling businesses to meet customer demands promptly and efficiently.

The Future of Custom Apparel with DTF Technology

The future of custom apparel is being shaped significantly by DTF technology. As advancements continue to enhance the capabilities of DTF printing, we can expect to see more innovative designs and applications being developed. Businesses that incorporate DTF transfers into their offerings will likely be at the forefront of the apparel market, as they adapt to ever-changing consumer preferences for personalized products.

Looking ahead, staying informed about the latest DTF innovations will be essential for industry players. With evolving techniques and improved materials, the possibilities for unique customizations are virtually limitless. Whether for high-volume production or small-batch crafting, DTF printing ensures that businesses can remain agile and competitive in an increasingly personalized market.

Frequently Asked Questions

What are DTF transfers and how do they work in T-shirt printing?

DTF transfers, or Direct to Film transfers, utilize a unique printing technology that involves printing vibrant designs onto a special film. These printed films are then applied to T-shirts or other garments using a heat press. This process ensures that the designs are long-lasting and suitable for various materials, making DTF transfers a popular choice for custom apparel.

What are the advantages of using DTF printing for custom apparel?

DTF printing offers several advantages for custom apparel, including high-quality prints with vibrant colors, versatility across different fabric types, and less waste due to its digital nature. Additionally, DTF transfers allow for quick turnaround times and have no minimum order requirements, making them ideal for small businesses and crafters.

Is DTF transfer printing a cost-effective solution for T-shirt printing?

Yes, DTF transfer printing is a cost-effective solution, particularly for small businesses and startups. It requires less initial investment in equipment compared to traditional printing methods like screen printing. Moreover, DTF technology minimizes material waste and setup times, making it budget-friendly for custom apparel production.

How durable are DTF prints when used for T-shirts and custom apparel?

DTF prints are known for their durability. They can withstand numerous washes without fading or peeling, which is essential for high-usage garments. This durability ensures that custom T-shirts maintain their vibrant appearance over time, appealing to customers looking for quality apparel.

Can DTF transfers be used on different fabric types?

Absolutely! DTF transfers are versatile and can be applied to a wide range of fabrics, including cotton, polyester, and blended materials. This flexibility makes DTF printing an excellent choice for businesses aiming to create diverse custom apparel products.

How does the DTF printing process compare to traditional T-shirt printing methods?

The DTF printing process differs significantly from traditional methods like screen printing. DTF transfers involve a digital printing approach, which minimizes setup times and material waste. Unlike screen printing, which requires multiple screens for different colors, DTF allows for complex, multi-color designs to be printed directly onto film, streamlining the production process.

| Key Points | Description |

|---|---|

| What is DTF Transfer Printing? | A technology that allows full-color designs to be printed onto a film and applied to garments using heat. |

| High-Quality Prints | Produces vibrant colors and fine details for special designs. |

| Versatility | Applicable to various materials including cotton and polyester. |

| Less Waste | Reduced material waste due to a digital process compared to screen printing. |

| No Minimum Orders | Many services offer no minimum order requirements, beneficial for small businesses. |

| Quick Turnaround | Fulfills orders faster due to advancements in DTF technology. |

| Customization | Allows unique designs that enhance brand appeal. |

| Cost-Effectiveness | A more affordable entry point into custom apparel for small businesses. |

| Easy Application | Simple process of printing, cutting, and heat pressing. |

| Durability and Washability | DTF prints can endure multiple washes without fading. |

| Scalability | Can easily scale to larger orders without lengthy setup times. |

Summary

DTF transfers are revolutionizing the custom T-shirt printing industry by offering a unique blend of high-quality, personalized designs with ease of use and efficiency. The DTF transfer method stands out due to its ability to deliver vibrant prints that are versatile across various materials, ensuring businesses can cater to diverse customer needs. Moreover, the elimination of minimum order requirements and reduced ink waste presents an attractive option for small enterprises and individual crafters alike. With continuous innovations and advancements in DTF printing technology, this method will undoubtedly maintain its growth and popularity in the market, making it an essential consideration for anyone looking to thrive in the custom apparel space.