DTF transfers, or Direct-to-Film transfers, have emerged as a game-changer in the world of custom printing, marrying ease of use with vibrant colors and intricate design capabilities. However, like any innovative method, DTF transfers are not without their challenges, with users frequently encountering DTF printing issues that can affect the final product’s quality. From adhesion problems to ink compatibility, potential pitfalls can derail even the most ambitious printing projects. Thankfully, troubleshooting DTF transfers is a manageable task with the right knowledge, and we’re here to provide expert DTF transfer tips that will enhance your workflow and outcomes. By understanding and addressing common DTF film problems, you can achieve remarkable prints that will impress your clients and elevate your business.

Known as Direct-to-Film printing, this technique allows printers to transfer intricate designs onto garments with remarkable ease. Often referred to simply as DTF, this method relies on high-quality films to create durable transfers that stand the test of time. However, like other printing methods, users may face obstacles that can hinder the quality of their projects. In navigating these challenges, solutions for DTF transfer issues become vital, equipping users with the tools they need to maximize their results. From understanding the importance of ink and film compatibility to refining your transfer processes, exploring effective DTF transfer solutions can significantly enhance your print quality.

Understanding DTF Transfer Adhesion Challenges

Adhesion issues are among the most common hurdles faced by those new to the DTF printing process. Many users report that their transfers do not adhere well to fabrics, resulting in peeling or flaking after washing. This problem often stems from insufficient heat application or incorrect pressure settings on the heat press. Achieving the right conditions, typically around 305°F for 10 to 15 seconds, is crucial for ensuring a strong bond between the DTF transfer and the garment.

To enhance adherence, pre-pressing garments can be immensely beneficial. By eliminating moisture and smoothing out any wrinkles prior to applying the DTF transfer, users can significantly improve the bonding process. Additionally, paying attention to the fabric type is essential; certain materials may require alternative settings or specific treatment to facilitate better adhesion.

Troubleshooting DTF Film Problems

DTF film problems often lead to unsatisfactory prints that fail to meet client expectations. A frequent complaint among users is the quality of the film itself. Low-grade films may not properly release ink during the transfer process, resulting in washed-out colors and blurry designs. Investing in high-quality DTF films, such as those from trusted brands like Gimmesource or Kohei, can dramatically improve the end results by ensuring effective ink release and a solid bond to the fabric.

Additionally, checking for any damage or defects in the film before use is imperative. Users should inspect for any scratches, bubbles, or uneven surfaces that could impair the transfer. By addressing these film problems early on, you can save both time and materials, leading to a smoother production process.

DTF Printing Issues: Maintenance and Care

Regular maintenance is a cornerstone of successful DTF printing, particularly when it comes to preventing issues like clogged print heads. Print heads should be cleaned regularly, especially before significant printing jobs, to avoid interruptions caused by dried ink or debris. Some professionals recommend conducting regular cleaning cycles after every printing session to ensure the machine runs optimally and produces clear, vibrant designs every time.

Moreover, users should also ensure that the ink supply is adequate and that they are using inks that are compatible with their specific DTF film. Using mismatched products can lead to a host of printing issues, including insufficient color vibrancy and inconsistent transfer quality. Investing in quality inks and committing to routine maintenance can make a substantial difference in the reliability of the DTF printing process.

Expert Tips for Achieving Optimal DTF Transfers

When it comes to maximizing the quality of DTF transfers, there are several expert tips to keep in mind. Firstly, ensuring that you are using the correct garment preparation techniques can significantly influence the outcome. Check the fabric for any contaminants that may hinder adhesion and always pre-press to remove moisture.

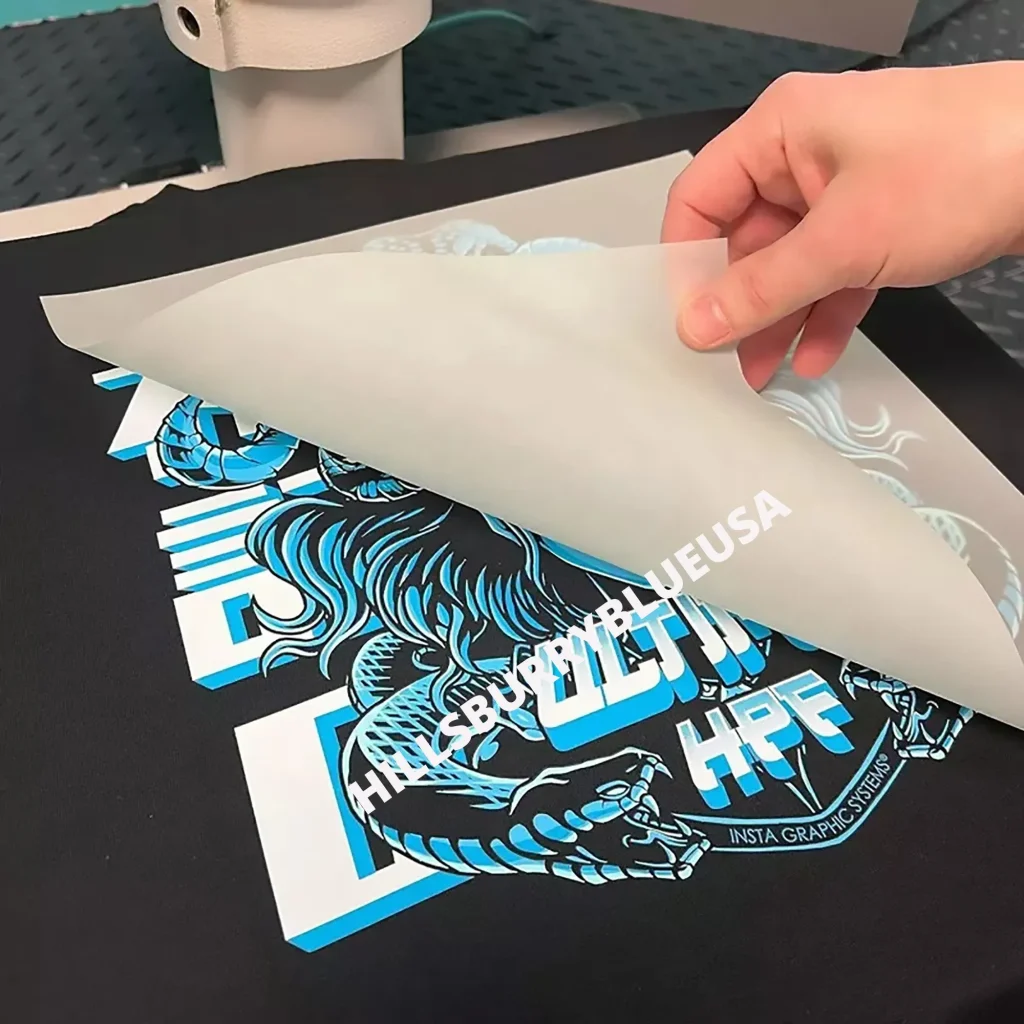

Additionally, incorporating a second pressing or employing a cold peel method after the initial transfer can add durability to your prints. This post-transfer treatment reinforces the adherence of the design and can drastically improve the lifespan of the print, making it more resilient against washing and wear.

Community Insights and Resources for DTF Printing

Joining the DTF printing community can provide invaluable insights and troubleshooting tips for overcoming common issues. Online forums and blogs such as Printavo and Your Design Online frequently offer expert advice tailored to users facing specific challenges. Engaging with community members on platforms like Reddit can also yield creative solutions and firsthand experiences that are beneficial for both novice and experienced printers.

Additionally, attending webinars or workshops hosted by industry professionals can deepen your understanding of DTF technology. These events provide a platform to learn about the latest advancements, explore different techniques, and ask questions directly related to DTF transfer challenges, thus enhancing your overall skill set in this dynamic field.

Navigating DTF Transfer Challenges: Final Thoughts

While DTF transfers present numerous challenges, addressing these issues methodically can lead to remarkable results. Understanding the nuances of temperature, adhesion, and material quality is key to successful print production. When problems do arise, utilizing the resources available in the community can provide the additional support needed to overcome these hurdles.

As you continue to refine your DTF printing techniques, embrace the learning process. Each challenge you face is an opportunity to grow and enhance your skills, ultimately leading to stunning DTF transfers that satisfy both you and your clients. Committing to high-quality materials and ongoing education will ensure your success in this exciting and evolving field.

Frequently Asked Questions

What are common troubleshooting tips for DTF transfers?

When troubleshooting DTF transfers, focus on common issues such as adhesion problems, ink compatibility, and clogged print heads. Ensure you are using the correct heat settings and quality materials. Regular maintenance of the printing equipment can also prevent many issues.

How do I resolve adhesion problems in DTF transfers?

To tackle adhesion problems in DTF transfers, confirm that your heat press is set to approximately 305°F for 10-15 seconds. Pre-press the garment to eliminate moisture and ensure a clean, smooth surface is prepared before applying the transfer.

What should I do if I face DTF printing issues?

If you encounter DTF printing issues, check for clogged print heads and ensure the ink is compatible with the transfer film. Regular cleaning of the print heads and using high-quality DTF inks can significantly improve print quality and reduce issues.

Can DTF film problems affect transfer quality?

Yes, DTF film problems can severely impact transfer quality. It’s essential to choose high-grade transfer films designed for DTF applications to ensure optimal ink release and a strong bond with the fabric. Always test different brands to find the best match for your needs.

What are the best DTF transfer tips for beginners?

For beginners in DTF transfers, prioritize using quality materials, maintain proper temperature and pressure settings, and prep garments thoroughly. Following these tips will help you avoid common pitfalls and achieve successful transfers.

What post-transfer treatments can enhance DTF transfer durability?

To enhance the durability of DTF transfers, consider a secondary pressing with a cover sheet or using a cold peel method after the initial heat pressing. These techniques reinforce the adhesion of the design to the garment, leading to longer-lasting results.

| Issue | Description | Solutions |

|---|---|---|

| Adhesion Problems | Poor adherence of DTF film to garments. | Maintain proper heat (305°F) and pressure, pre-press to eliminate moisture. |

| Ink Compatibility | Incompatibility can affect color vibrancy and transfer quality. | Use high-quality inks and films specifically designed for DTF. |

| Clogged Print Heads | Clogged heads disrupt printing process. | Perform routine cleanings and maintenance of print heads. |

| Film Quality | Quality of film affects overall print success. | Invest in reliable brands like Gimmesource or Kohei. |

| Correct Prepping of Garments | Dust or oils can hinder adhesion. | Ensure surfaces are clean and smooth before application. |

| Post-Transfer Treatment | Secondary heat press can enhance durability. | Use a cover sheet for a second pressing or cold peel method. |

Summary

DTF transfers have emerged as a game-changing technology in the custom printing landscape, offering unmatched flexibility and exceptional color accuracy. However, like any innovative technique, navigating it involves overcoming various challenges. By understanding key issues such as adhesion problems, ink compatibility, and maintenance of equipment, users can significantly improve their printing results. Emphasizing quality materials, proper prep work, and utilizing professional resources for continuous learning aids in minimizing common pitfalls associated with DTF transfers. Therefore, remaining proactive and engaged with the broader printing community will not only enhance individual skills but also lead to consistently outstanding DTF printing outcomes.