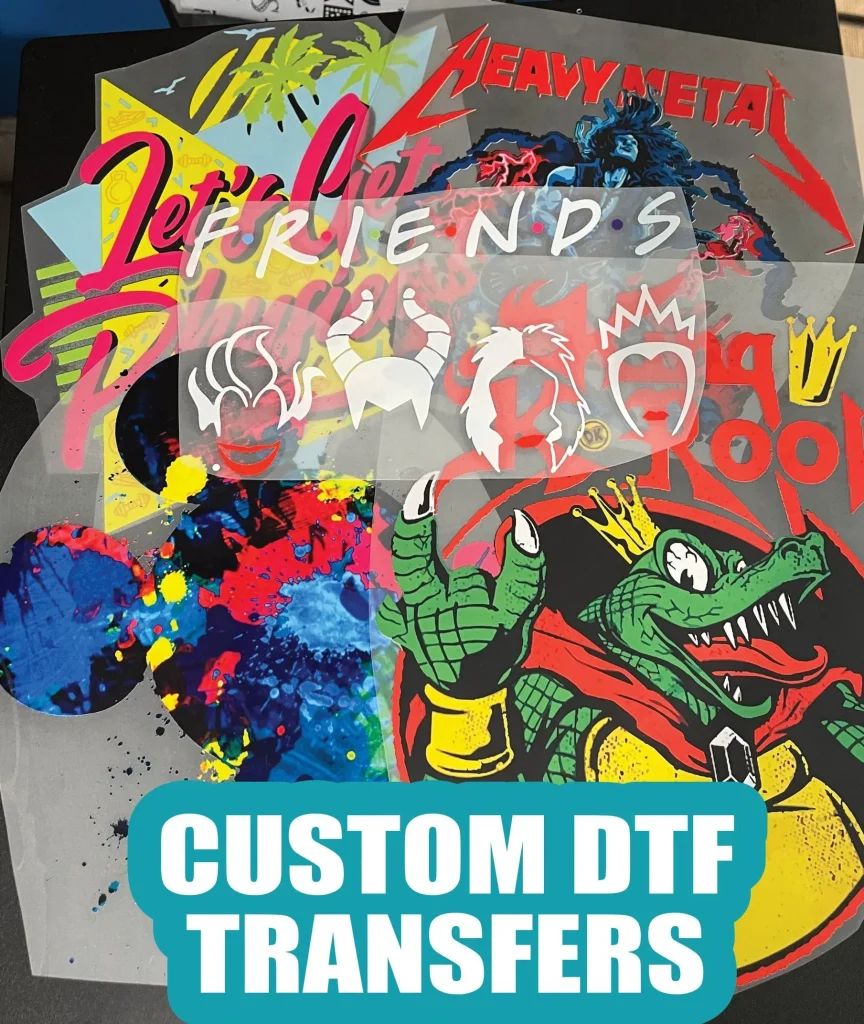

DTF transfers, short for Direct-to-Film transfers, have quickly become a game-changer in the world of custom apparel printing. This innovative printing method offers a seamless way to create vibrant and durable designs, making it appealing not only to beginners but also to experienced artists and entrepreneurs. Whether you are looking to launch your own clothing line or simply want to personalize your wardrobe, understanding the DTF printing process is essential. In this complete beginner’s guide to DTF, we will delve into its many advantages, the equipment you’ll need, and tips to ensure your printing endeavors are successful. With DTF transfers, the possibilities are endless, and mastering this technique can lead to stunning results.

Known variously as Direct-to-Film printing or simply DTF printing, this method transforms the custom apparel landscape, offering a fresh approach to fabric decoration. By utilizing specialized films and inks, this printing process allows for striking image reproduction on numerous garment types, catering to the needs of both novice users and seasoned professionals. As we explore the benefits of DTF transfers, we will uncover how this technique compares to traditional methods, enhancing your printing capabilities and opening doors for creative expression. From understanding the essential equipment required to mastering the heat transfer process, we will guide you through every aspect of DTF printing to help kick-start your journey in custom apparel creation.

Understanding the DTF Printing Process

The DTF printing process encompasses a series of critical steps that culminate in the creation of high-quality prints on various fabrics. At its core, DTF stands for Direct-to-Film printing, which differs from traditional methods like screen printing. Initially, a design must be generated using specialized graphic design software. This design is then transferred onto a film through a DTF printer equipped with vibrant, water-based inks. The transfer film is uniquely designed to absorb the ink, ensuring that the image will retain its integrity when heat-pressed onto fabric.

Once the design is printed, an adhesive powder is applied to the surface of the film while the ink is still wet, providing a strong bond to the fabric when heat is applied. The film is then placed under a heat source to cure the adhesive, solidifying the inks and preparing them for transfer. A heat press is essential for the final step, which involves applying heat and pressure to adhere the printed image to the garment, allowing for precise detail and color resolution. This unique process enables both beginners and experienced printers to create stunning apparel that is both durable and visually appealing.

Key Advantages of DTF Transfers for Custom Printing

DTF transfers offer several compelling advantages that make them stand out in the realm of custom apparel printing. One of the primary benefits is their versatility; DTF printing works seamlessly on a broad array of fabrics, including cotton, polyester, and blends, as well as dark and challenging materials. This capability allows businesses to cater to diverse customer preferences, opening up a market filled with creative possibilities. Additionally, DTF transfers yield exceptionally high-quality prints, characterized by vibrant colors and intricate details. This quality elevates designs, making them not only visually appealing but also durable enough to withstand regular wear and washing.

Another significant advantage is the cost-effectiveness of DTF printing, especially when it comes to small production runs. Traditional screen printing often requires large orders to be financially viable, leaving small businesses and hobbyists at a disadvantage. However, DTF transfers allow for short runs and customizable designs without a hefty financial investment, making it accessible for newcomers venturing into the custom apparel printing space. This makes DTF a fantastic solution for anyone looking to explore the world of custom clothing while managing their budget effectively.

Essential Equipment for Successful DTF Printing

Before embarking on your DTF printing journey, it’s crucial to gather the necessary equipment to ensure optimal results. At the forefront, a reliable DTF printer is indispensable. Many enthusiasts and small business owners frequently opt for well-regarded models from brands such as Epson or Roland, renowned for their print quality and compatibility with DTF inks. Alongside the printer, a heat press is vital for transferring designs onto fabric. Choosing a high-quality heat press will facilitate accurate temperature and pressure settings, yielding professional results.

In addition to these two primary pieces of equipment, aspiring printers must also procure DTF transfer film and adhesive powder. The transfer film should possess specific properties that allow for ink absorption and durability during the transfer process. Similarly, selecting the right adhesive powder plays a critical role; it must be fine enough to ensure a smooth application yet strong enough to adhere the design securely during and after the heat transfer process. By investing in high-quality supplies, beginners can significantly enhance their printing output and minimize challenges along the way.

Getting Started: A Beginner’s Guide to DTF Printing

For those excited to dive into DTF printing, starting on the right foot is essential. As a beginner, your first focus should be on familiarizing yourself with the DTF printing process and the equipment involved. Invest time in learning about the software used for design creation, as a well-crafted design is the cornerstone of any successful DTF project. Additionally, understanding how to configure your printer settings based on the fabric type is crucial. Each material may require unique adjustments, including ink density and heat application.

As you experiment, embrace the learning curve that comes with mastering heat press techniques. Fine-tuning temperature, pressure, and timing will play a pivotal role in achieving the best transfer quality. Many beginners find value in exploring online resources, such as tutorials on YouTube or forums on platforms like Reddit, where they can connect with fellow enthusiasts. These communities can provide support, troubleshooting tips, and inspiration as you progress on your DTF journey.

Emerging Trends in DTF Printing

The DTF printing landscape is continuously evolving, bringing forth exciting trends that enhance the industry for both newcomers and established businesses. As custom apparel demand surges, technology advancements are making DTF printing more accessible. Newer printers are being developed that not only consume less ink but also produce high-quality outputs at a faster rate. This allows small business owners to operate more efficiently and meet growing consumer demands without compromising quality.

Moreover, as sustainability becomes a key concern in the printing industry, many manufacturers are innovating eco-friendly inks and materials tailored for DTF printing. These advancements not only appeal to environmentally conscious consumers but also position businesses to thrive in a market that prioritizes sustainability. Keeping abreast of these trends is essential for anyone looking to succeed in the custom apparel sector, as they provide insights into market shifts and consumer preferences, ultimately guiding product development.

Resources for Mastering DTF Printing

For beginners and seasoned printers alike, a wealth of educational resources exists to help deepen understanding of DTF printing techniques. Online platforms like YouTube host numerous channels dedicated to DTF printing tutorials, providing visual guidance to navigate equipment setup, troubleshooting common issues, and perfecting the printing process. Engaging with these tutorials can significantly shorten the learning curve for novices, helping them avoid common pitfalls standout on their creative journey.

Additionally, online communities on platforms such as Facebook and Reddit have quickly become invaluable resources for DTF printing enthusiasts. Members share experiences, offer tips, and discuss challenges they face, fostering a collaborative environment for learning and growth. For anyone interested in mastering DTF printing, these communities are a treasure trove of information, inspiration, and support that can empower printers to unlock their full potential in the exciting world of custom apparel.

Frequently Asked Questions

What are DTF transfers and how do they work in custom apparel printing?

DTF transfers, or Direct-to-Film transfers, are a modern printing technique where images are printed onto a special film and then heat-pressed onto fabric. This method starts with a digital design printed onto DTF transfer film using specialized inks. After applying adhesive powder and curing, the film is transferred to garments, creating vibrant and durable designs. This process is popular in custom apparel printing for its versatility and high-quality output.

What are the advantages of using DTF transfers compared to traditional printing methods?

DTF transfers offer several advantages over traditional printing methods like screen printing. They provide greater versatility, allowing prints on various fabrics including cotton and polyester. The quality of DTF prints is exceptional, offering bright colors and intricate designs that last well over time. Moreover, DTF is cost-effective for small runs and custom projects, making it ideal for both hobbyists and small businesses.

What essential equipment is needed for the DTF printing process?

To start with DTF transfers, you will need specific equipment including a quality DTF printer, a heat press for transferring designs onto fabric, DTF transfer film, and adhesive powder. Having these tools ensures you can create high-quality custom apparel prints using the DTF printing process.

Can you provide a beginner’s guide to the DTF printing process?

A beginner’s guide to the DTF printing process involves several key steps: First, create your design in graphic software, then print it onto the DTF transfer film using specialized inks. While the ink is still wet, dust the film with adhesive powder and cure it with heat. Finally, align the film on your garment and use a heat press to transfer the design. Mastering these steps will lead to successful DTF transfers.

What tips can help beginners improve their DTF transfer techniques?

Beginners looking to improve their DTF transfer techniques should invest in high-quality supplies including films and inks. It’s also important to experiment with printer settings based on fabric type for optimal results. Additionally, mastering heat press techniques, such as correct temperature and pressure settings, will greatly enhance the quality of your DTF prints.

What resources are available for learning more about DTF transfers?

There are numerous resources for learning about DTF transfers, including YouTube channels that provide tutorials and tips on DTF printing. Online communities on platforms like Reddit and Facebook also offer support and advice from experienced users. Blogs and websites focusing on DTF printing, such as the Printful blog, provide in-depth guides and industry insights, making them valuable for both beginners and advanced users.

| Key Points | Details |

|---|---|

| What is DTF Transfer? | DTF is a printing technique that prints images onto a special film applied to fabric, using specialized inks and a heat press for durability. |

| Advantages of DTF Transfers | 1. Versatile on multiple fabrics (cotton, polyester, dark materials) 2. High-quality, vibrant prints 3. Cost-effective for small runs and custom designs. |

| Required Equipment | 1. DTF printer 2. Heat press 3. DTF transfer film and adhesive powder |

| Process Steps | 1. Design creation in graphic software 2. Print on DTF film 3. Apply adhesive while ink is wet 4. Heat transfer to garment using a heat press. |

| Tips for Beginners | 1. Invest in quality supplies 2. Experiment with printer settings 3. Master heat press techniques |

| Industry Trends | Increasing popularity in small business due to rising demand for custom apparel and advancements in technology. |

| Resources for Learning | 1. YouTube tutorials 2. Online communities (Reddit, Facebook groups) |

Summary

DTF transfers have transformed the custom apparel printing landscape, making it accessible and efficient for both beginners and seasoned printers alike. As an innovative method, DTF transfers offer high-quality prints with vibrant colors on various fabrics, ensuring durability and cost-effectiveness. This process demystifies the art of printing, allowing anyone to create stunning designs with the right tools and knowledge. With continuous advancements in technology and a supportive learning community, mastering DTF transfers is not just a possibility but an exciting opportunity for creativity and entrepreneurship in the custom apparel industry.