DTF transfers have revolutionized the realm of high-quality fabric printing, emerging as a preferred choice for designers and businesses alike. This cutting-edge DTF printing technology enables the creation of stunning, vibrant designs on a vast array of fabrics, effectively meeting the demands of custom apparel printing. What sets DTF transfers apart is their eco-friendly printing process, which optimizes material use and reduces waste, aligning perfectly with the trend towards sustainable printing solutions. As the fashion industry increasingly prioritizes sustainability, DTF transfers have become an essential tool for those focused on high-quality fabric printing while maintaining environmental integrity. In this article, we will delve into the advantages of DTF transfers and explore their impact on modern printing practices.

Often referred to as Direct-to-Film printing, DTF transfers represent an innovative approach to high-resolution fabric decoration. This technique allows for versatile applications across various textile types, catering to the growing demands of customized clothing and merchandise. The DTF printing method stands out for its ability to produce intricate and vibrant graphics, appealing to both commercial enterprises and individual creators. Moreover, the eco-conscious aspect of DTF technology aligns with contemporary trends in sustainable manufacturing, positioning it as a go-to option for brands seeking high-quality fabric solutions without compromising on environmental responsibilities. Embracing this advanced printing method could pave the way for a new era in custom fabric artistry.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology has transformed the landscape of fabric printing, providing artists and businesses with an efficient means to achieve stunning, high-quality graphics on a variety of materials. Unlike traditional methods that rely on direct ink application to surfaces, DTF utilizes a unique process whereby ink is printed onto a special film, which is subsequently transferred onto fabric using heat. This technology allows for an unmatched level of detail and vivid colors, making it a favorite among custom apparel creators who want to make statements with their designs.

Moreover, the versatility of DTF printing extends to its compatibility with different fabric types, including cotton, polyester, and blends, which opens doors for various applications ranging from high-end fashion to promotional merchandise. This adaptability is crucial as the demand for personalization and diversity in apparel escalates. As brands shift towards unique offerings, DTF technology stands out as a reliable solution that meets their needs for high-quality fabric printing.

The Environmental Impact of DTF Transfers

In today’s world, eco-consciousness shapes many industries, and fabric printing is no exception. DTF transfers are at the forefront of sustainable printing solutions. By producing less waste compared to traditional screen printing and sublimation methods, DTF not only conserves resources but also promotes more eco-friendly manufacturing practices. The ability to print detailed designs without excessive ink usage directly contributes to lowering the environmental footprint of custom apparel production.

Furthermore, the materials used in DTF printing are designed to be more environmentally friendly, aligning with global efforts towards sustainability. Brands adopting DTF technology demonstrate their commitment to ‘green’ practices, appealing to consumers who value sustainability. This eco-friendly printing method supports an industry’s pivotal shift towards responsibility while maintaining the high-quality standards that today’s consumers expect.

Investing in the Future of Custom Printing

The future of DTF printing looks promising, buoyed by significant investments in technology and processes that enhance productivity and quality. Companies like Eazydtf are pivotal in this landscape, revamping large-format DTF printing machinery to cater to the growing demands of custom apparel production. This influx of resources ensures that businesses can produce intricate designs with higher durability and color fidelity, crucial for gaining a competitive edge in today’s saturated market.

In addition, as DTF technology becomes more sophisticated, the affordability and accessibility for small businesses increase. This accessibility creates opportunities for budding entrepreneurs and crafters to bring their ideas to life without the high costs associated with traditional printing setups. As DTF technology continues to evolve, it represents not only a smart investment for businesses but also holds the potential to democratize high-quality fabric printing for anyone looking to innovate.

Custom Apparel: Advanced Printing Solutions with DTF

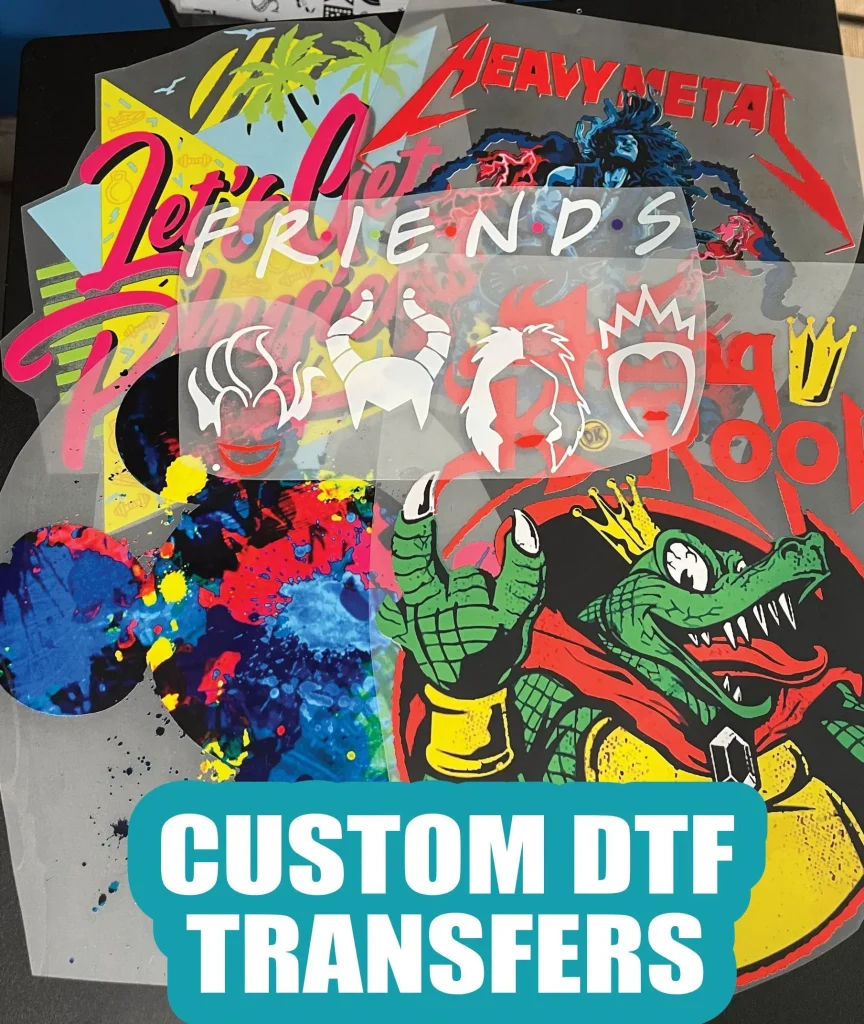

As the trend for personalized fashion continues to soar, DTF transfers provide an ideal solution for businesses specializing in custom apparel. The introduction of services like DTFPrinter’s new custom transfer options has made it easier for designers to navigate the complexities of fabric printing while delivering exceptional results. These new offerings ensure that vibrant colors and sharp details align with the creator’s vision, allowing for a seamless transition from concepts to finished products.

The capability of DTF printing to handle complex designs and a variety of fabric types sets it apart as a leader in the field of custom printing. Whether it’s creating promotional t-shirts or designing unique outfits for special occasions, DTF technology meets the diverse needs of customers. This versatility, combined with high-quality output, makes DTF transfers a go-to choice for anyone looking to make a mark in the world of custom apparel.

Comparing DTF Transfers to Other Printing Methods

When examining DTF transfers alongside traditional printing techniques such as screen printing and sublimation, several advantages emerge that showcase the superiority of DTF technology. For instance, while sublimation is restricted to synthetic fabrics, DTF transfers can be applied to a wider range of fabrics, including cotton. This versatility allows businesses to cater to an expansive customer base, providing custom solutions for every type of garment.

Additionally, the durability of DTF prints—able to withstand multiple washes without fading—positions it as a more reliable choice for consumers. This longevity is a significant selling point for brands prioritizing quality and performance in their products. With vibrant color reproduction and detailed imagery possible through DTF, the comparison against conventional methods underscores a shifting paradigm in the fabric printing landscape.

The Growing Market for DTF Printing Solutions

As DTF printing technology continues to gain traction, the market for these solutions is expanding rapidly worldwide. New entrants in the printing industry, such as AM.CO.ZA in South Africa, are making DTF printing accessible to micro and small businesses. Their compact and affordable DTF printers empower local entrepreneurs to explore the possibilities of custom printing and garment decoration, fostering creativity and economic growth in their communities.

Furthermore, as interest in DTF transfers surges, educational resources and support networks are becoming increasingly available, enabling users to maximize their potential with this cutting-edge technology. This growth trajectory is not only elevating the quality standards across the market but also promoting innovation through creative collaborations among designers, crafters, and established businesses.

Frequently Asked Questions

What are DTF Transfers and how do they work in high-quality fabric printing?

DTF transfers, or Direct-to-Film transfers, are a revolutionary technology in high-quality fabric printing that allows for detailed designs to be printed onto films and then transferred onto various fabric surfaces. This process involves printing your design on a specific film that is coated with adhesive, which later bonds the ink to the fabric, producing vibrant and durable prints suitable for a wide range of materials.

Why are DTF Transfers considered eco-friendly printing solutions?

DTF transfers are considered eco-friendly printing solutions because they minimize waste and utilize materials more efficiently compared to traditional methods. The DTF printing process focuses on reducing excess materials and energy usage, which aligns with the growing demand for sustainable printing practices in the apparel industry.

How do DTF Transfers compare to other custom apparel printing methods?

DTF transfers stand out in comparison to other custom apparel printing methods like sublimation and screen printing mainly due to their versatility and fabric compatibility. DTF can be used effectively on various fabric types, including cotton and polyester, whereas sublimation is limited to polyester fabrics. Additionally, DTF prints are known for their vibrancy and durability, making them a preferred choice for intricate and high-resolution designs.

What advantages do DTF Transfers offer for small businesses in the custom printing industry?

DTF transfers provide numerous advantages for small businesses, such as lower investment costs in printing technology and the ability to create high-quality, customized designs without needing extensive resources. The accessibility of compact DTF printers enables small business owners and freelancers to enter the custom garment printing market, offering diverse products that meet consumer demands.

What types of fabrics can be printed using DTF Transfers?

DTF transfers can be used on a wide range of fabrics, including cotton, polyester, nylon, and blended fabrics. This versatility makes DTF printing an ideal choice for various applications in the custom apparel printing industry, allowing creators to experiment with different materials without compromising on print quality.

Are DTF Transfers durable and suitable for repeated washing?

Yes, DTF transfers are known for their durability. The prints produced using this technology can withstand numerous washes without significant fading or loss of quality, making them suitable for everyday wear and enhancing their appeal in the custom apparel market.

| Key Points | Details |

|---|---|

| Versatility | DTF transfers can be applied to various fabric types such as cotton, polyester, nylon, and mixed fabrics, unlike traditional methods which may have limited compatibility. |

| Environmental Benefits | DTF processes are designed to minimize waste and environmental impact, appealing to brands looking for sustainable printing options. |

| Investment in Technology | Significant investments in DTF technology, such as those by Eazydtf, enhance printing capabilities and allow for intricate, durable designs. |

| Customized Printing | New services from companies like DTFPrinter provide high-quality, custom DTF prints, supporting the needs of crafters and designers. |

| Comparison to Other Methods | DTF excels in vibrancy, detail, and fabric compatibility compared to sublimation and screen printing. |

| Market Accessibility | Compact DTF printers are being introduced in various markets, making DTF technology more accessible to small businesses and freelancers. |

Summary

DTF Transfers are reshaping the landscape of high-quality printing on any fabric, offering a sustainable solution that meets the demands of today’s designers and businesses. This innovative method stands out for its versatility, allowing vibrant and durable prints across a variety of materials, from natural fibers to synthetics. As the printing industry evolves, DTF Transfers not only promise an eco-friendly approach but also cater to the creative needs of a diverse audience, including both professionals and hobbyists. Ongoing advancements in technology and increased market accessibility further position DTF printing as a leading choice for custom applications, ensuring its relevance in the ever-changing fabric printing sector.