High-quality gangsheets are at the heart of efficient custom apparel printing, significantly impacting the results of the Direct-to-Film (DTF) printing process. This modern printing technique revolutionizes the creation of vibrant designs and intricate graphics that capture attention. DTF printing harnesses advanced Direct-to-Film technology, allowing for outstanding color vibrancy and detail reproduction, making it a game-changer in the world of printing techniques. By utilizing high-quality gangsheets, businesses can increase their production capabilities while maintaining a standard of excellence in printing. As sustainability practices gain momentum, the shift towards eco-friendly DTF printing solutions further enhances the appeal of this innovative process.

Understanding the essence of high-quality transfer sheets is vital for anyone venturing into the realm of advanced garment decoration. These specialized sheets facilitate the efficient application of designs onto fabrics through cutting-edge printing methods, leading to impressive results. Employing innovative techniques such as Direct-to-Film printing ensures that designs are not only vivid but also long-lasting, appealing to modern consumers’ demanding standards. The beauty of utilizing such transfer media lies in its adaptability, allowing creators to push the boundaries of their artistic vision while adhering to sustainable practices. Ultimately, becoming familiar with these versatile printing methods can unlock new opportunities in the custom apparel landscape.

The Benefits of High-Quality Gangsheets in DTF Printing

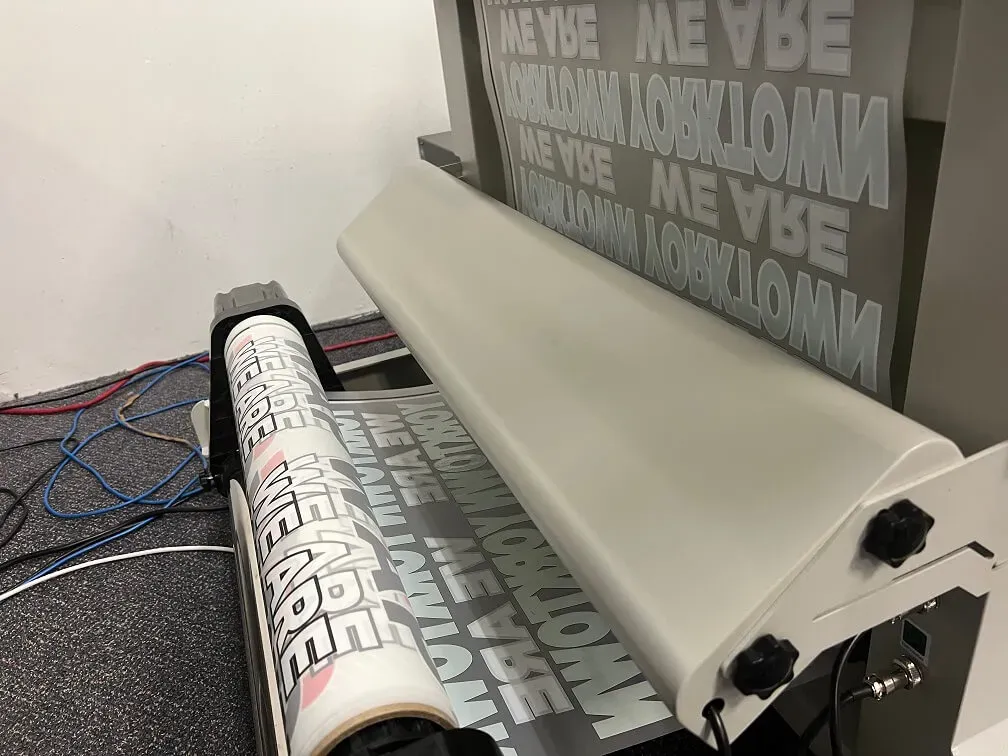

High-quality gangsheets play a pivotal role in the Direct-to-Film (DTF) printing method by consolidating multiple designs into a single sheet for efficient production. This process is incredibly beneficial for businesses, as it allows for the simultaneous printing of numerous graphics, reducing waste and maximizing the use of film. With vibrant colors and detailed designs printed on high-quality gangsheets, it becomes easier for brands to deliver eye-catching products that appeal to a broad audience. The efficiency and effectiveness of high-quality gangsheets not only save time but also lower production costs, making them a smart choice for any printing business.

Moreover, the versatility of high-quality gangsheets is invaluable, especially in the realm of custom apparel printing. Businesses can quickly adapt and modify designs to reflect current trends or seasonal demands while maintaining a standard of excellence in quality. This flexibility allows companies to satisfy a diverse customer base, often leading to increased sales and customer loyalty. High-quality prints from gangsheets also ensure that colors remain vibrant and details remain crisp even after repeated washing, thereby enhancing customer satisfaction and reducing returns.

Direct-to-Film Technology Explained

Direct-to-Film (DTF) technology represents a transformative approach to the printing industry, enabling intricate designs and vibrant colors to be printed directly onto fabric. This innovative method involves transferring specialized inks onto a treated film, which is then applied to the garment using heat and pressure. Unlike traditional methods, like screen printing that may struggle with fine details, DTF provides an elegant solution for complex designs. Moreover, the rapid advancements in DTF equipment have bolstered the technology’s capacity, allowing for faster printing times without sacrificing quality.

One of the critical advantages of DTF technology is its capability to execute customization in high volumes without compromising on print quality. Businesses can produce anything from simple logos to elaborate artwork with consistent results, which is essential in today’s demand for personalized products. Furthermore, DTF printing caters to sustainable printing efforts by utilizing eco-friendly inks, thereby reducing the ecological impact of printing. As the popularity of DTF grows, so does its potential to reshape the landscape of custom apparel printing.

The DTF Printing Process: Simplified

The DTF printing process is a systematic approach that, when mastered, can yield outstanding results in graphic printing. The process begins with design creation, where graphics are carefully crafted using design software. This ensures that the layout is optimized for the films being used, allowing for a maximized yield of each print. Next, the design is printed using high-quality DTF inks onto a specialized film, ensuring every detail of the original graphic is preserved. Each step, from printing to transferring, is designed to maintain the integrity of the artwork.

Once the film is printed, it undergoes a curing process to set the inks before being applied to the fabric. This requires precise heat and pressure to ensure that the design adheres correctly and maintains its vibrancy. Finishing touches are critical; any excess film is meticulously removed, and the final product is inspected for quality assurance. This attention to detail throughout the DTF printing process is what guarantees high-quality output, making it crucial for any print shop looking to excel in custom apparel.

Advancements in DTF Printing Technologies

The DTF printing landscape is continually evolving with innovations that enhance efficiency and quality. Modern advancements include the use of high-performance printers that can handle greater volumes at faster speeds, accommodating the rising demand for personalized apparel while keeping costs low. These printers not only improve output but also incorporate advanced ink formulations that enhance adhesion to various fabrics, resulting in durable prints that withstand multiple washes.

Moreover, the shift towards sustainability within the DTF printing industry has led many companies to adopt eco-friendly inks, minimizing their environmental footprint. This trend not only attracts environmentally conscious consumers but also reaffirms the industry’s commitment to sustainability. With ongoing advancements, DTF technology promises a future where high-quality gangsheets are produced more efficiently, allowing businesses to thrive in an increasingly competitive marketplace.

Market Trends in DTF Printing

Recent market trends indicate a significant surge in the adoption of Direct-to-Film printing technology. Small businesses and custom printing shops are increasingly favoring DTF due to its cost-effectiveness and enhanced flexibility in production. The ability to create customized apparel quickly and efficiently aligns perfectly with the growing demand for personalized merchandise, leading to a robust expansion of the sector. Market analysts predict that this trend will continue, as the appetite for unique and customized products persists.

Furthermore, as DTF technology becomes more accessible, even smaller players in the printing industry can compete in the personalized merchandise market, traditionally dominated by larger companies. This democratization of technology means that innovative startups can leverage high-quality gangsheets to offer unique, tailored products that resonate well with niche audiences. Stay tuned to shifting trends and consumer preferences, as they will inevitably shape the future landscape of custom apparel printing.

Navigating Challenges in DTF Printing

While DTF technology offers numerous advantages, it is not without its challenges. The initial investment in DTF equipment can be daunting for newcomers, with costs of printers and supplies potentially hindering those just entering the market. Moreover, the technical aspects of DTF printing require a learning curve; understanding how to optimize print settings and achieve the best results is essential. Many aspiring printers may feel overwhelmed, but with resources available, any business can become proficient in the art.

Additionally, mastering the intricacies of DTF printing is crucial for delivering consistent quality. As the market continues to expand, navigating these challenges will become imperative for businesses seeking a competitive edge. Fortunately, there is an abundance of online communities and tutorial resources tailored for DTF printing enthusiasts. These platforms offer valuable insights into optimizing technology and troubleshooting common issues, creating a supportive network for new and seasoned printers alike.

Frequently Asked Questions

What are high-quality gangsheets in DTF printing?

High-quality gangsheets refer to the optimized layouts of designs printed using Direct-to-Film (DTF) technology. They enable efficient use of film by consolidating multiple designs onto a single sheet, ensuring vibrant colors and intricate details are preserved in the final print.

How does DTF printing improve the quality of gangsheets?

DTF printing enhances the quality of gangsheets by employing specialized inks that produce vivid colors and sharp graphics. This technique ensures that even complex designs maintain their vibrancy and clarity, making it ideal for custom apparel printing.

What printing techniques are best for creating high-quality gangsheets?

The best printing technique for creating high-quality gangsheets is DTF printing due to its innovative technology. It combines the use of advanced inks and a precise transfer process, resulting in durable and visually striking prints compared to traditional methods.

How can I ensure sustainability when producing high-quality gangsheets?

To ensure sustainability while producing high-quality gangsheets, opt for eco-friendly inks and practices in your DTF printing process. Many suppliers now offer sustainable printing options that minimize environmental impact without compromising print quality.

What are the main advantages of using DTF technology for custom apparel printing?

The main advantages of using DTF technology for custom apparel printing include its ability to produce high-quality, durable prints, even on intricate designs. Additionally, DTF printing is cost-effective and allows for quick production of personalized items, making it a preferred choice among businesses.

Can beginners effectively use DTF technology to create high-quality gangsheets?

Yes, beginners can effectively use DTF technology to create high-quality gangsheets. While the learning curve may present challenges, there are numerous online resources, tutorials, and community support available to help newcomers master the necessary skills.

| Key Aspect | Details |

|---|---|

| Introduction to DTF Printing | Essential for creating high-quality printed materials with vivid colors and intricate details. |

| Benefits of DTF Technology | Produces vibrant prints with great detail; softer to the touch and ideal for intricate designs. |

| DTF Printing Process | 1. Design Creation 2. Printing 3. Transfer 4. Finishing Touches |

| Market Trends | Growing adoption by businesses due to cost-effective and personalized merchandise demand. |

| Challenges | High equipment costs and need for technical know-how can deter newcomers. |

| Community and Resources | Abundant online tutorials and community support for enhancing DTF printing techniques. |

Summary

High-Quality Gangsheets are a pivotal element in the evolution of Direct-to-Film (DTF) printing technology. This method revolutionizes print quality and offers unparalleled flexibility, making it the go-to choice for producing customized apparel. Emphasizing vibrant colors and intricate designs, high-quality gangsheets not only stand out in the competitive market but also fulfill the growing consumer demand for personalized products. Although challenges such as equipment costs and the learning curve exist, accessible resources and community support make the transition to DTF printing more manageable. As the industry continues to innovate, the potential for high-quality gangsheets will only expand, further integrating into the fabric of modern print solutions.